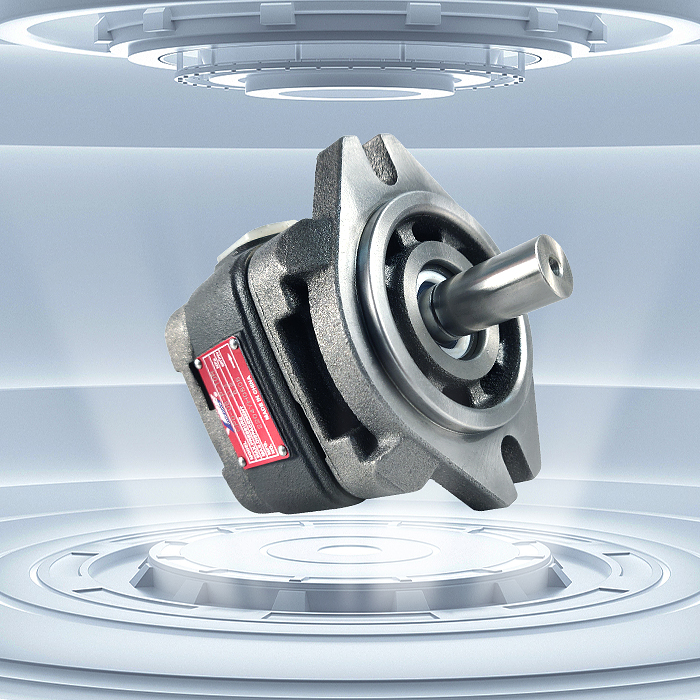

5 faults of gear pump in hydraulic system

1. The pump does not come out of oil

If it is found that the gear pump does not come out of oil during the debugging of the main engine, first check whether the rotation direction of the gear pump is correct. Gear pumps are divided into left and right rotation. If the rotation direction is wrong, the pressure oil formed by the volume difference generated by the meshing of the internal gears will cause the oil seal to be washed out and oil will leak. Secondly, check whether the oil filter at the oil inlet end of the gear pump is blocked, which will make it difficult or impossible to absorb oil, and cause the oil suction hose to be sucked off.

2. The oil seal is flushed out

(1) The rotation direction of the gear pump is wrong. When the rotation direction of the pump is not correct, the high-pressure oil will directly pass to the oil seal. Since the low-pressure skeleton oil seal can withstand the pressure of 0.5MPa at most, the oil seal will be flushed out.

(2) The gear pump bearing bears the axial force. The generation of axial force is often related to the tight fit between the shaft extension end of the gear pump and the coupling sleeve. That is, the pump shaft is subjected to a backward axial force when the pump is installed with a hammer or by hard pulling the mounting screws. When the pump shaft When rotating, the subsequent axial force will force increased wear in the pump. Since the inside of the gear pump is sealed by the fit and seal of the gear end face and the shaft sleeve end face, when the axial seal end face is severely worn, a certain gap will be generated in the axial seal inside the pump, resulting in high and low pressure oil chambers and the oil seal rushing out. This kind of situation occurs frequently in the dump truck industry, mainly due to the wrong size of the coupling sleeve on the main engine.

(3) The gear pump bears excessive radial force. If the coaxiality of the gear pump is not good when it is installed, the radial force on the pump will exceed the bearing limit of the oil seal, which will cause the oil seal to leak. At the same time, it will also cause damage to the floating bearing inside the pump.

3. No pressure or not enough pressure

This phenomenon is mostly related to the cleanliness of the hydraulic oil. If the oil is not selected correctly or the cleanliness of the oil in use does not meet the standard requirements, it will accelerate the internal wear of the gear pump and cause internal leakage.

4. The traffic is not up to the standard

(1) The oil inlet filter element is too dirty and the oil absorption is insufficient;

(2) The installation height of the pump is higher than the self-priming height of the pump;

(3) The oil suction pipe of the gear pump is too thin, resulting in large oil suction resistance;

(4) The air leakage of the oil suction port joint causes insufficient oil suction of the oil pump. You can judge whether the system is leaking by observing whether there are air bubbles in the fuel tank.

5. Fever

(1) The system is overloaded, mainly when the pressure or speed is too high.

(2) The cleanliness of the oil is poor, the internal wear is intensified, the volumetric efficiency is reduced, and heat is generated from the internal gap leakage and throttling.

(3) The oil outlet pipe is too thin and the oil flow rate is too high.