Features of hydraulic vane pump

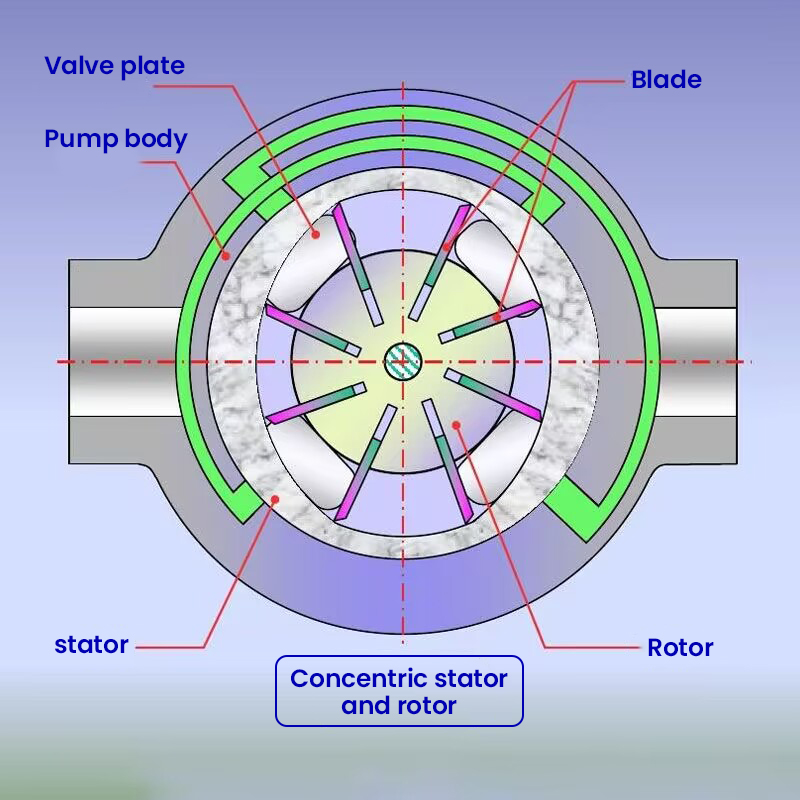

The core component of the vane pump (hydraulic motor) is a set of rectangular vanes that can expand and contract radially in the chute. They divide the annular space formed between the front and rear end covers, the rotor and the stator along the circumference into closed spaces with the same number of vanes. room. Since the radial distance between the rotor and the stator changes along the circumference, the volume of these closed chambers will expand and contract periodically during the rotation of the rotor. On the end cover or stator of the pump (occasionally on the casing or on the fixed center pin), there are separate waist-shaped flow distribution windows, and the oil suction chamber communicates with the closed chamber that is expanding the volume area. The oil discharge chamber communicates with the closed chamber in the area where the volume is being reduced, so as to complete the oil suction and discharge process. The function of the blade is to form a sealed "partition wall" between the closed chambers, and its telescopic movement is used to compensate the change of the distance between the rotor and the stator.

Features of single acting vane pumps:

1.trapped oil phenomenon

Because the sealing angle between the suction and oil discharge windows of the valve plate is greater than the angle between two adjacent vanes, the stator of the single-acting vane pump does not have an arc segment concentric with the rotor. Therefore, in the oil suction and oil discharge transition zone, when the sealed cavity between the two blades changes, the phenomenon of oil trapping similar to that of the gear pump will occur. In order to solve the phenomenon of trapped oil, a triangular unloading groove is usually opened on the edge of the oil discharge window of the distribution plate.

2.oil through the root of the blade

When the rotor rotates, if only relying on the centrifugal force to make the blades protrude outward, it cannot ensure that the blades are in full contact with the pump body. In this case, the suction oil chamber cannot be formed at all, resulting in failure of the pump. In order to solve this problem, the pressure oil is passed through the root of the blade to make the blade fully contact with the pump body.

3.blade inclination

The vane of the single-acting vane pump is close to the surface of the stator by centrifugal force in the oil-absorbing area, and forms a variable-volume sealed space with the stator, rotor, and distribution plate. In order to make the resultant force on the vane consistent with the sliding direction of the vane, ensure that the vane It is easier to slide out of the vane slot, which is often machined to slope backwards at a certain angle along the direction of rotation.

4.Unbalanced radial force One side of the single-acting vane pump rotor is the oil discharge chamber for high-pressure oil, and the other side is the oil suction chamber for low-pressure oil. The rotor and bearing of the pump will bear a large hydraulic pressure, which makes the working pressure of the pump And the improvement of displacement is subject to certain restrictions.

5.Flow pulsation The flow of the single-acting vane pump also has pulsation, the more the number of vanes in the pump, the smaller the flow pulsation rate. The pulsation rate of the pump with odd number of vanes is smaller than that of the pump with even number of vanes, so the number of vanes of single-acting vane pumps is all odd, generally 13 or 15.

Double acting vane pump features:

If the blade thickness of the double-acting vane pump is not considered, the output flow of the pump is uniform, but the actual blade has thickness, and the long-radius arc and short-radius arc cannot be completely concentric, especially the groove at the bottom of the blade and the pressure oil chamber. Therefore, the output flow of the pump will fluctuate slightly, but its pulsation rate is much smaller than that of other types of pumps (except screw pumps), and it is the smallest when the number of blades is an integer multiple of 4. Therefore, the number of vanes of the double-acting vane pump is generally 12 or 16.