HG series internal gear pump

Product Composition:

The internal gear pump adopts axial and radial pressure compensation design, and maintains high volume ratio even at low speed and low viscosity.

It adopts high-strength cast iron and unique sound-absorbing design inside to make the noise lower.

The internal gear pump is not sensitive to oil pollution, has a long service life and low noise, and the maximum pressure can reach 35 MPa. The maximum speed can reach 3000r/min.

Product Composition:

HG series internal gear pump.

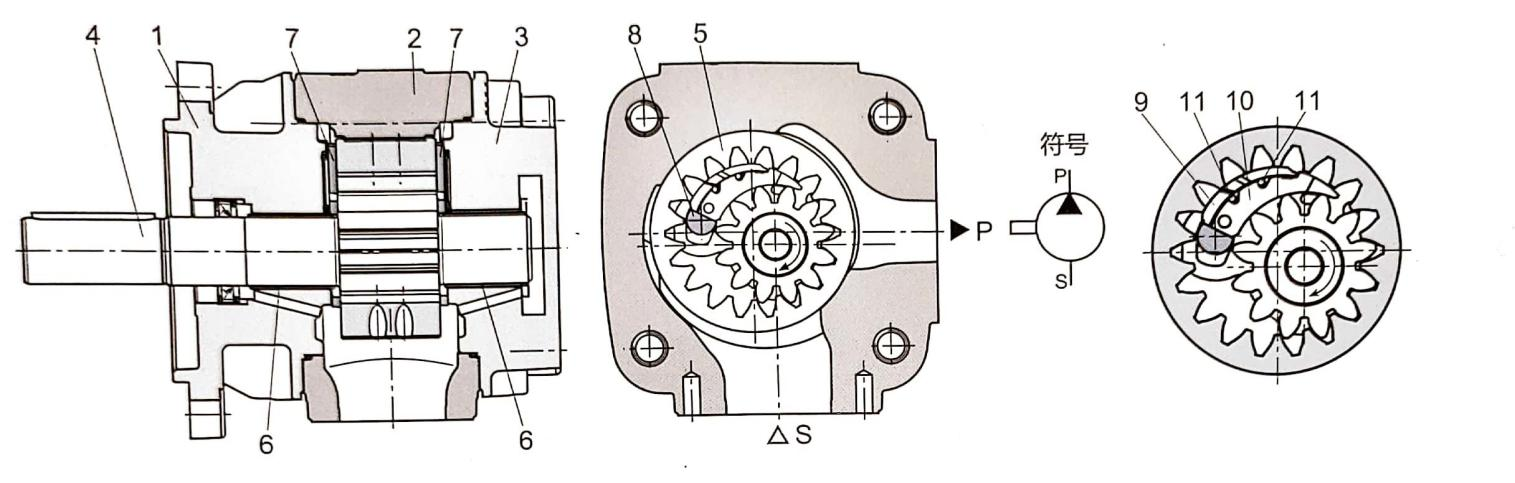

Its basic composition consists of: front cover (1), pump body (2), rear cover (3), gear shaft (4), inner ring gear (5), sliding bearing (6), front and rear side plates (7), positioning Rod (8) and crescent secondary plate (9), crescent main board (10) and plastic rod (11) are formed.

Applications:

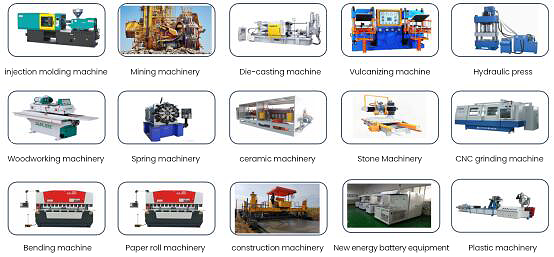

It is widely used in hydraulic systems of injection molding machines, bending machines, die-casting machinery, forklifts and other industries. It is perfectly combined with servo control motors to achieve economic benefits of energy saving, consumption reduction and emission reduction.

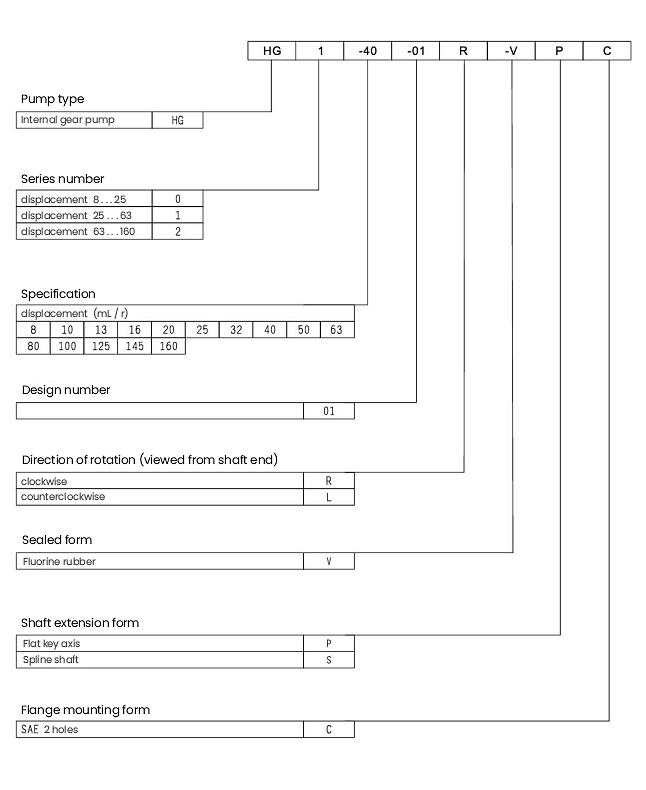

Model Description:

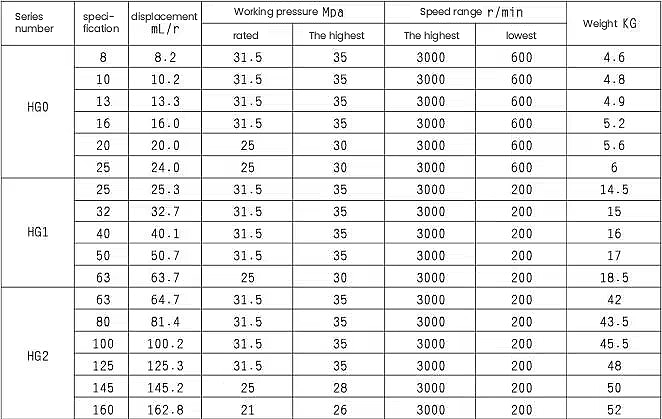

Performance parameters:

Precautions for use:

1. Working medium

Petroleum-based mineral oil with a viscosity range of 10-300mm²/s can be used, and ISO VG46 anti-wear hydraulic oil is recommended.

2. Working temperature

Working temperature range -10°C - 100°C, in order to ensure long-term reliable life, the best working temperature range is 20-80°C.

3. Cleanliness control

It is required to control the cleanliness level of the oil in the system, not exceeding Class 9 (NAS 1638) or 17/14 (ISO 4066)

4. Pump installation

The connection between the shaft and the motor uses a flexible coupling as much as possible to avoid bending moment or axial thrust. The maximum allowable concentricity error between the shaft and the motor shaft is less than 0.15mm.

5. Suction port pressure and piping

The absolute pressure at the suction port is allowed to be 0.2-2 Bar. Reasonable piping diameter should not be smaller than the oil suction port of the pump to ensure the best oil suction speed of 0.6-1.2m/s on average.

6. Import and export connection

Try to avoid hard connection of steel pipes for the oil inlet and outlet pipes, and it is recommended to use rubber hoses to avoid extra loads and extra noise.

7. Exhaust

Before the initial operation, you should fill the pump with oil or add an exhaust valve to remove the air in the pump and the system pipeline. If there is air in the pump or in the pipeline, it will cause vibration and noise of the pump, and indirectly affect the service life of the pump.

8. Maintenance

In order to improve the service life of the pump, the system should be regularly checked for abnormal vibration, noise, oil temperature, whether there are bubbles in the oil tank and whether there is leakage, etc., and timely maintenance.