How an internal gear pump works

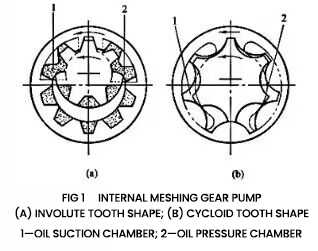

Currently commonly used internal gear pumps have two types of tooth profile curves: involute gear pumps and cycloidal gear pumps (also known as rotor pumps) (see Figure 1). Their working principles and main features are similar to those of external gear pumps. basically the same. The pinion is a driving gear. When it rotates in the direction shown in the figure, the gear exits the meshing volume to increase and absorb oil, and the gear entering the meshing volume decreases to press oil. In the involute tooth-shaped internal gear pump chamber, a crescent-shaped partition should be installed between the pinion and the internal gear to separate the oil suction chamber from the pressure oil chamber [see Figure S(a)]. The pinion and the internal gear of the cycloidal internal gear pump have a difference of one tooth, so there is no need to set up a partition [see Figure 1 (b)]. The internal meshing gear pump has the advantages of compact structure, small size, light weight, stable operation, small flow pulsation, low noise, and high volumetric efficiency when working at high speed. Because the gears rotate in the same direction, the relative sliding speed between the gears is small, the wear is small, and the service life is long; but the tooth shape is complicated, the processing is difficult, and the price is higher than that of the external gear pump.

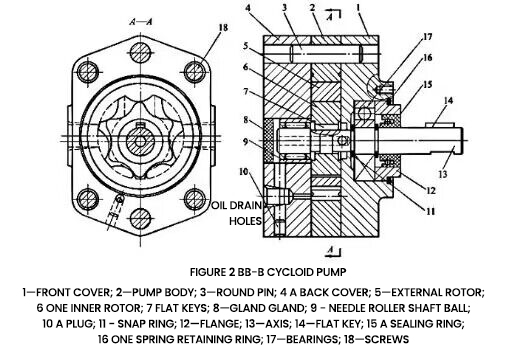

At present, there are many kinds of cycloid pumps in China. Figure 2 shows the structure diagram of the BB-B type cycloid pump developed by a machine tool factory in 1975. Its maximum working pressure is ≤2.5MPa. BB-B type internal meshing cycloidal gear pump is a positive displacement internal gear pump. .

Because the pump has the characteristics of simple structure, low noise, stable oil delivery, good self-priming performance and high speed, it is widely used in low-pressure hydraulic systems. It is widely used in machine tools, gearboxes, compressors, transmission machinery, lifting and unloading machinery and other hydraulic systems with mechanical pressure lower than 2.5MPa. It can be used as a power pump, lubricating pump and cooling pump, and is suitable for conveying various oils. .

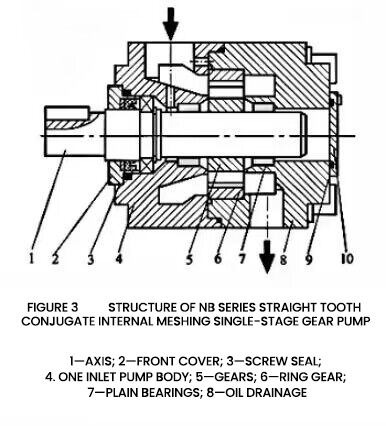

Figure 3 shows the NB series internal meshing gear pump. The structure of the NB series internal meshing gear pump is a straight tooth conjugate internal meshing single stage gear pump.

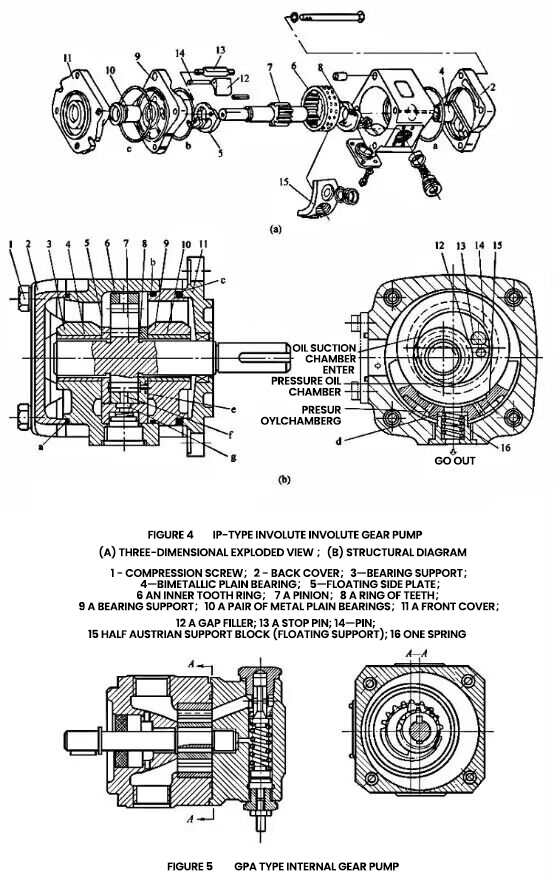

Figure 4 shows the IP type involute internal gear pump.

Figure 5 shows the GPA type internal gear pump.