How many connection methods are there for hydraulic valves?

Various hydraulic valves are often seen in the hydraulic system, so what are the connection methods of the hydraulic valves? The editor tells you that the connection methods of hydraulic valves include pipe connection, plate connection, manifold type and superimposed valve type, etc., and I will introduce them to you separately below.

1. Tube connection

Pipe connection, also known as threaded connection, connects pipe hydraulic valves with pipe joints and oil pipes, and flanges for large flow rates. Its advantage is that the direction of the oil between the valves in the system is clear at a glance; the disadvantage is that the structure is scattered, the space occupied by the hydraulic system is large, the sections are staggered, it is not easy to assemble, disassemble and maintain, and the pipe joints are easy to leak oil and enter air, and it is easy to Vibration and noise are generated. There are few applications at present.

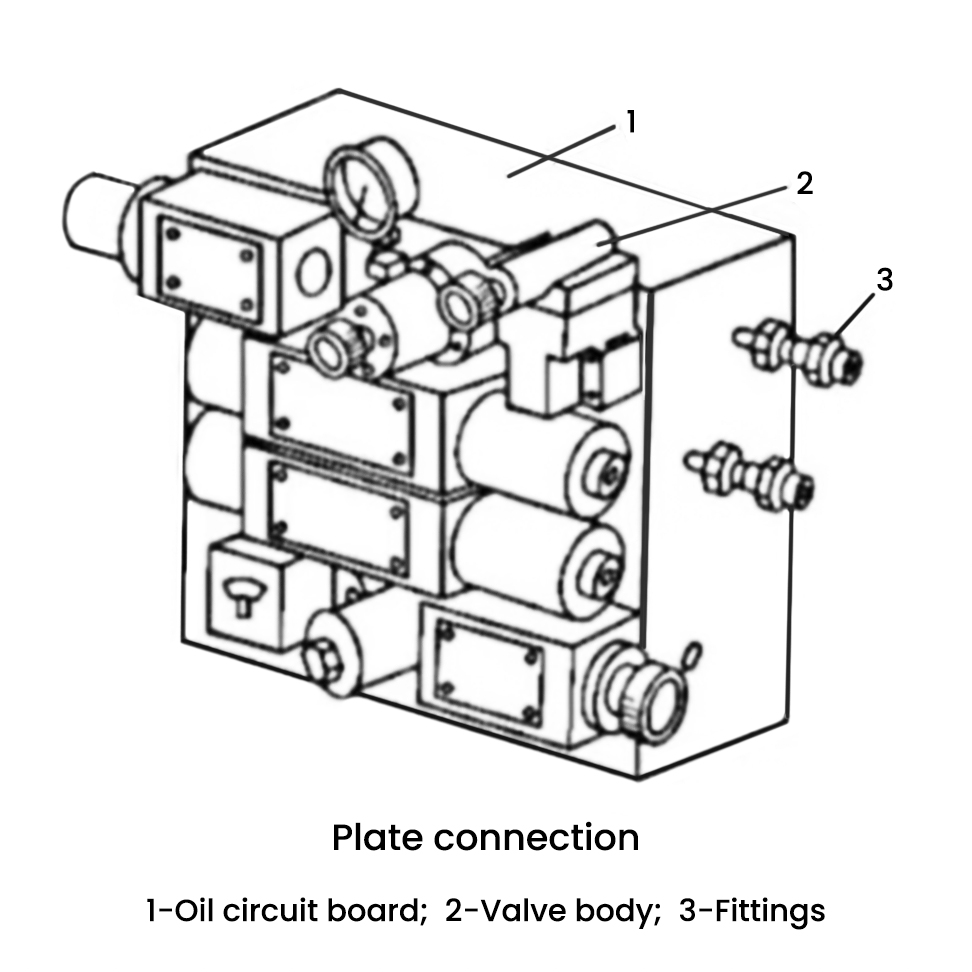

2. Plate connection

As shown in Figure 2, the plate connection is to uniformly install the plate hydraulic valve on the connecting plate, and the connecting plate used has the following forms.

(1) Single-layer connection plate: valve components are installed in front of the vertical connection plate, and the oil circuit between valves is connected with oil pipes behind the plate. This kind of connecting plate is simple, and it is convenient to check the oil circuit, but there are many pipelines on the plate, so it is inconvenient to assemble and disassemble.

(2) Double-layer connecting plate: The oil circuit connecting the valve is processed between the two plates. The two plates are fixed together with adhesives or screws. The process is simple and the structure is compact. However, when the pressure of the hydraulic station system is high, leakage is easy to occur. Oil string cavity problem.

(3) Integral connection plate: The integral connection plate is drilled or cast in a thicker connection plate as the connection oil circuit. It has a compact structure, fewer oil pipes, and reliable work, but it is difficult to process and the pressure loss in the oil circuit is large.

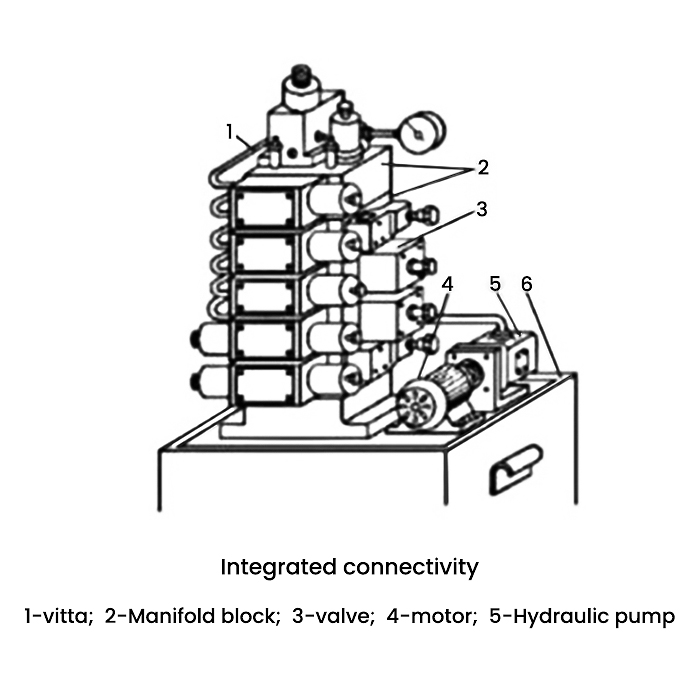

3. Integrated block type

As shown in Figure 3, the integrated block hydraulic device installs plate hydraulic components on three sides around the integrated block, and installs pipe joints on the other side, which are connected to the hydraulic actuators through oil pipes. The connecting oil circuit formed by drilling in the block, the block and the components installed around it form an integrated block group, which is usually a typical basic circuit that can complete a certain function, such as a pressure regulating circuit block, a speed regulating circuit block, etc. A hydraulic The system is often composed of several integrated block groups, and each integrated block is connected with the top cover and the bottom plate with long bolts. This connection form has the advantages of compact structure, few oil pipes, can be standardized, and is easy to design and manufacture. Therefore, it has been widely used in various hydraulic systems.

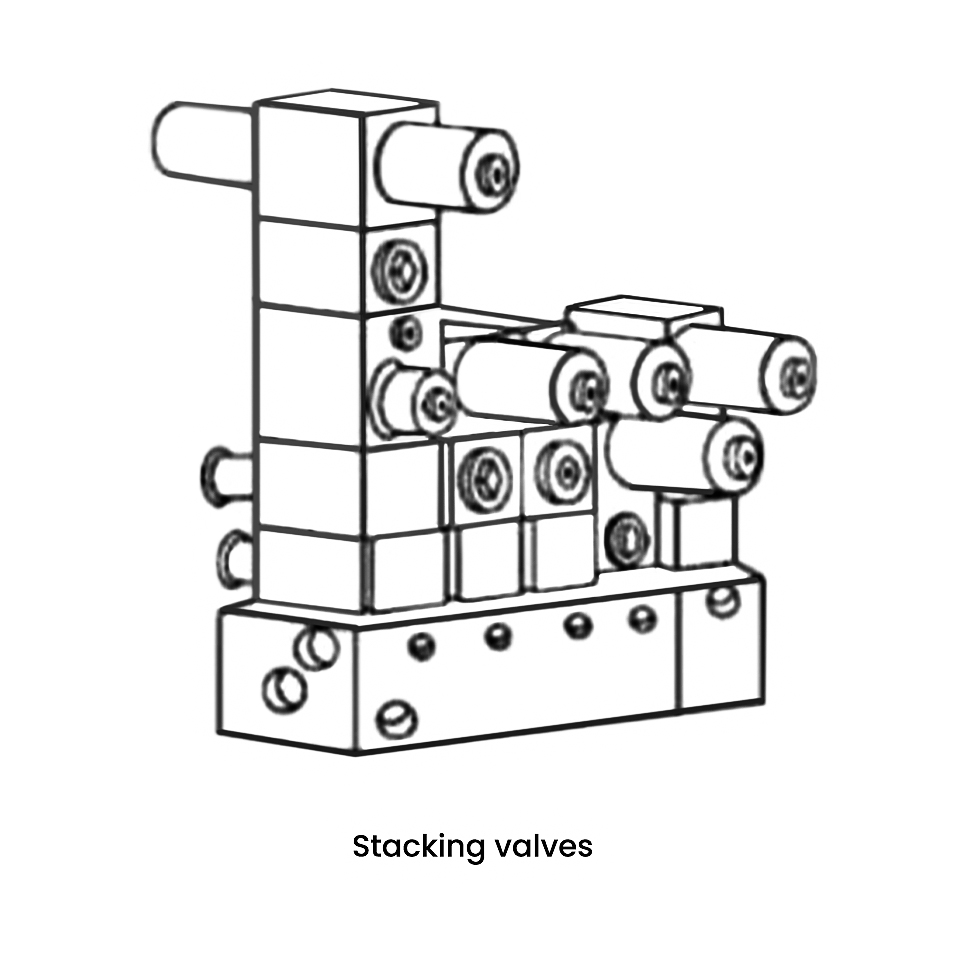

4. Superposition valve type

As shown in Figure 4, the superimposed valve type is another way of hydraulic device integration, and each superimposed valve not only acts as a control valve, but also acts as a channel body. Therefore, the superimposed valve configuration does not require additional connecting blocks, and the required hydraulic system can be formed by directly installing each superimposed valve on the bottom plate with long bolts.