【Hydraulic knowledge】Structure, working principle and flow factors of quantitative pump and variable pump (1)

1. The structure, working principle and flow factors of quantitative vane pump

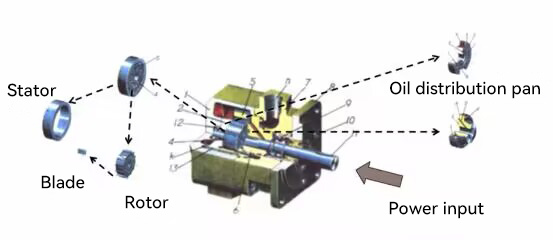

(1)The structure of quantitative vane pump

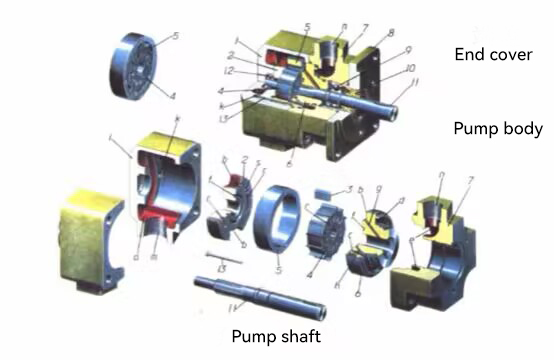

From the appearance, the main components of the double-acting vane pump are: the pump shaft, the end cover, and the pump body. When the pump body is opened, the main internal components are the stator, the rotor, the blades placed in the rotor blade slots, and the stator , the oil distribution plate at both ends.

The power is input from the pump shaft, which drives the rotor to rotate to complete the process of oil suction and pressure. How did he achieve oil absorption and oil pressure?

(2) Quantitative vane pump working principle

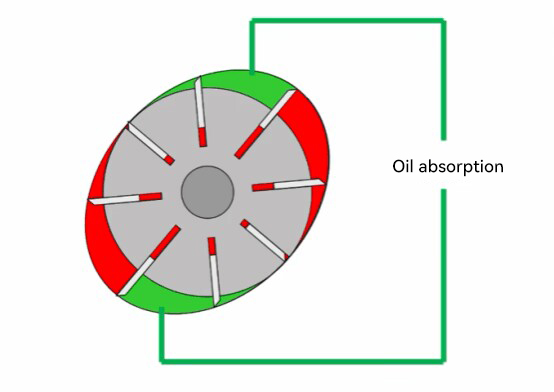

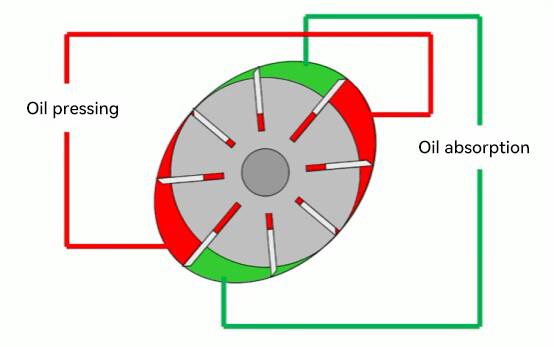

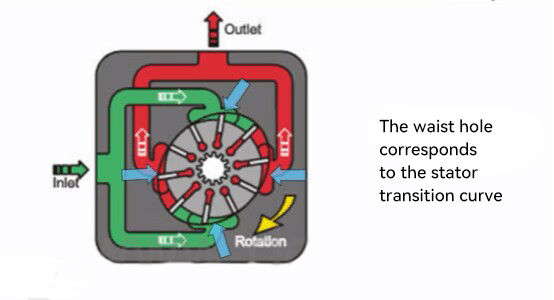

The inner surface of the stator, the outer surface of the rotor. The adjacent blades and the oil distribution plates at both ends form a closed space. Since the outer surface curve of the rotor is circular, and the inner surface of the stator is composed of two large-radius arcs, small-radius arcs at both ends and four transition curves, so The distance from the outer surface of the rotor to the inner surface of the stator is constantly changing. The arc of the large radius is the farthest, and the arc of the small radius is the closest. When the radius moves from the arc of the small radius to the arc of the large radius, under the centrifugal force When the blades move from the large-radius arc to the small-radius arc, the pressure on the inner surface of the stator is continuously retracted, so the space volume between adjacent blades is also constantly changing. If the rotor Turn clockwise, the volume space in the green area in the figure will become larger, and the oil pressure in the fuel tank will be pushed into the pump from the oil suction port under the action of the external atmospheric pressure to complete the oil suction process.

In the red area, the spatial volume is reduced. The oil is pressed out through the oil outlet to complete the oil pressing process.

In the process of one revolution of the pump shaft, two oil suction processes are completed, so it is called a double-acting vane pump. It should be noted that there is a waist-shaped hole on the oil distribution plate, which is the channel for the oil to enter and exit. When installing, the waist-shaped hole must correspond to the transition curve area of the stator.

In the process of one revolution of the pump shaft, two oil suction processes are completed, so it is called a double-acting vane pump. It should be noted that there is a waist-shaped hole on the oil distribution plate, which is the channel for the oil to enter and exit. When installing, the waist-shaped hole must correspond to the transition curve area of the stator.

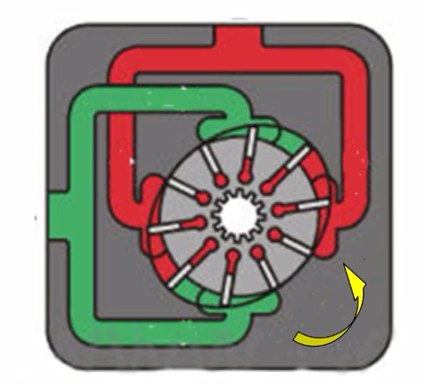

Radial force balance on the double-acting vane pump rotor: Due to the symmetrical distribution of the oil suction area and the oil pressure area, the radial force on the double-acting vane pump rotor is balanced.

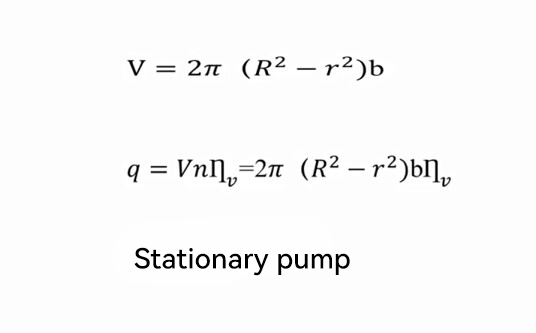

(3) Factors related to displacement and flow of quantitative vane pump

Among them, R represents the long radius of the stator, small R represents the short radius of the stator, and B represents the width of the vane. It can be seen from this that once the size of the parts is determined, the displacement of the double-acting vane pump cannot be modified. This hydraulic pump with non-adjustable displacement is called a fixed displacement pump.