Several reasons for the permanent deformation of the O-ring

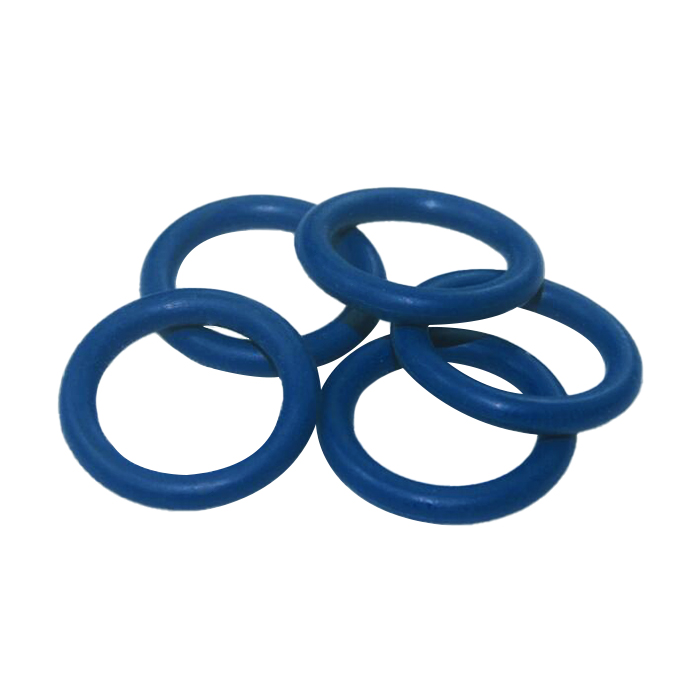

O-rings are the most widely used of all sealing products, the production process is relatively simple, and there are many materials used. The O-ring is a typical sealing effect produced by extrusion and deformation. When it is installed, it will generate contact pressure with the sealing surface. When the pressure is greater than the pressure of the sealing medium, the sealing effect will be produced, and when it is less than that, leakage will occur.

The reasons for the permanent deformation of the O-ring are as follows:

1. Factors of O-ring compression and stretching.

Due to the different formulations of O-ring rubber materials, the compression and stretching of O-rings produced by different companies are also different. Under long-term compression, the product will produce the imagination of compressive stress relaxation. This phenomenon will gradually expand with time. The longer the time, the smaller the amount of compression and stretching will be, making it less elastic and causing leakage. The most direct way to change is to increase the cross-sectional size of the product, but it will also lead to an increase in the structure of the product.

2. The relationship between the temperature and the relaxation process of the O-ring.

Temperature is very important to the relaxation degree of O-ring. No matter what kind of rubber material, it will accelerate its aging speed at high temperature. When the temperature in the environment is higher, the deformation of air compression will be greater. When the product is deformed When it exceeds 40%, the O-ring will slowly lose its elasticity and cause leakage.

3. The influence of medium working pressure on the deformation of o-ring.

Compared with the above two factors, the pressure of the medium has a greater impact on the deformation of the O-ring, which is the most common condition that causes the deformation of the O-ring in all working conditions. With the development of modern hydraulic equipment, The pressure of the hydraulic medium is getting higher and higher, and the O-ring working in this high-pressure environment for a long time will cause permanent deformation of the O-ring. This deformation is irreversible, so it should be selected according to different working pressures. For different materials, choose a relatively pressure-resistant rubber material. Correspondingly, in order to cope with higher working pressure, the hardness of the sealing ring of the pressure-resistant material will also increase accordingly.