Understand the skeleton oil seal

Today we continue to discuss another form of sealing that is most widely used in sealing - skeleton oil seal.

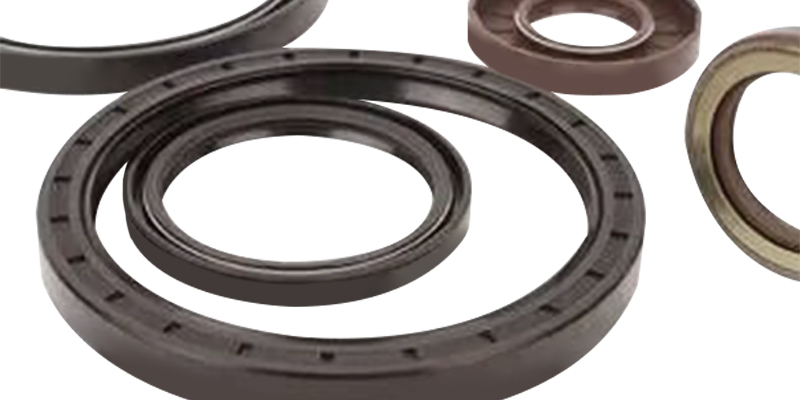

1. Structure of skeleton oil seal

The frame oil seal is mainly composed of an oil seal body, a reinforced frame and a self-tightening coil spring. Usually, the inner diameter of the skeleton oil seal in the free state is smaller than the shaft diameter, that is, it has a certain "interference". Therefore, when the oil seal is installed on the oil seal seat and the shaft, the pressure of the oil seal cutting edge and the contraction force of the self-tightening coil spring will produce a certain radial tightening force on the shaft. After a period of operation, the pressure will decrease rapidly or even disappear. , Therefore, adding a spring can compensate the self-tightening force of the oil seal at any time.

2. The sealing principle of the skeleton oil seal

There is an oil film controlled by the oil seal edge between the oil seal and the shaft, and this oil film has fluid lubrication characteristics. Under the effect of the surface tension of the liquid, the rigidity of the oil film just makes the oil film and the air contact end form a crescent surface, which prevents the leakage of the working medium and realizes the sealing of the rotating shaft.

The sealing ability of the oil seal depends on the thickness of the oil film on the sealing surface. If the thickness is too large, the oil seal will leak; if the thickness is too small, dry friction may occur, causing wear of the oil seal and shaft; if there is no oil film between the sealing lip and the shaft, it will easily cause heat and wear .

Therefore, when installing, you must apply some oil on the sealing ring, and at the same time ensure that the skeleton oil seal is perpendicular to the axis line. If it is not vertical, the sealing lip of the oil seal will drain the lubricating oil from the shaft, and it will also cause excessive sealing of the sealing lip. wear and tear. During operation, the lubricant in the casing seeps out a little to achieve the ideal state of forming an oil film on the sealing surface.

3. Correct use of skeleton oil seal

The skeleton oil seal is made of high-quality nitrile rubber and steel plate, with stable quality and long service life. Its main function is (1) to prevent sediment, dust, moisture, etc. from invading the bearing; (2) to limit the leakage of lubricating oil in the bearing.

Reasonable use of oil seals should pay attention to the following points:

(1) High-speed shafts should use high-speed oil seals, and low-speed shafts should use low-speed oil seals. Low-speed oil seals cannot be used on high-speed shafts, and vice versa;

(2) Ambient temperature In the case of high operating temperature, polypropylene or silicon, fluorine, or fluorosilicone rubber should be used, and efforts should be made to reduce the oil temperature in the fuel tank. When the operating temperature is too low, cold-resistant rubber should be selected;

(3) Under the condition of excessive pressure, a pressure-resistant support ring or a reinforced pressure-resistant oil seal should be used;

(4) Correctly install the skeleton oil seal. If the eccentricity of the oil seal and the shaft is too large, the sealing performance will be deteriorated, especially when the shaft speed is high. If the eccentricity is too large, the oil seal with "W" section can be used;

(5) The surface finish of the shaft directly affects the service life of the oil seal, that is, the high finish of the shaft will prolong the service life of the oil seal;

(6) Pay attention to the oil seal There should be a certain amount of lubricating oil on the lip;

(7) Pay special attention to prevent dust from infiltrating the oil seal.

4. Leakage cause analysis and solutions

4.1 Manufacturing reasons

4.1.1 Bad lip - poor manufacturing quality - burrs or defects on the lip - remove the burr or replace the oil seal

4.1.2 Poor quality or failure of springs - manufacturing quality - replace springs

4.1.3 The radial pressure is small - the spring is too loose, the radial clearance is too large - adjust the spring

4.2 Reason for assembly