What are the performance parameters of the vane pump, do you know?

The main performance of the vane pump is pressure, displacement, speed, efficiency and life, etc. The main structural parameters are the long and short radii of the curved surface of the stator slideway (double-acting vane pump).

(1) Pressure The working pressure of a single-acting variable vane pump generally does not exceed 17.5MPa. The maximum working pressure of the double-acting quantitative vane pump has reached 28-30MPa, which is slightly lower than that of the gear pump. The working pressure of the cam rotor vane pump can reach 21MPa.

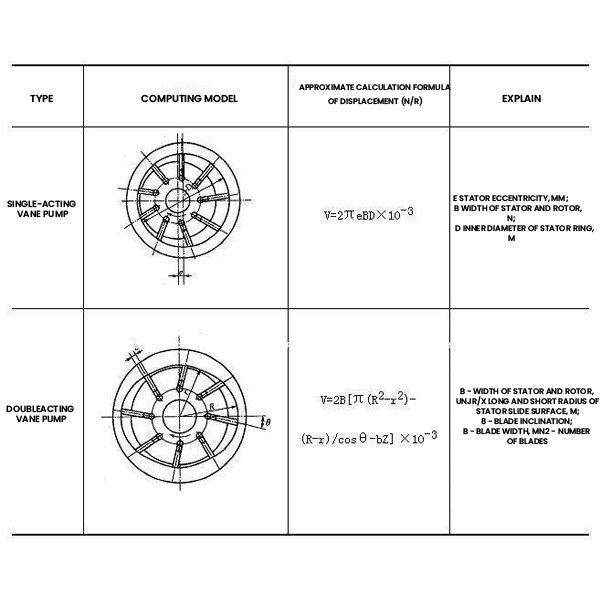

(2) Estimation and range of displacement The displacement of the vane pump mainly depends on the width of the stator and rotor, the inner diameter and eccentricity of the stator (single-acting vane pump), the long and short radii of the curved surface of the stator slideway (double-acting vane pump) ) and the number of blades, blade thickness, blade inclination, etc. The approximate calculation formula of vane pump displacement is shown in the table below.

Approximate calculation formula for vane pump displacement

It is known that the displacement range of common variable vane pump products is 6-120mL/r. The displacement range of double-acting vane pump products is 0.5-4200mL/r, but the commonly used displacement is 2.5-300mL/r.

(3) Speed The maximum speed of the commonly used single-acting variable pump is about 3000r/min, and there is also a minimum speed limit (generally 600-900r/min) to ensure sufficient centrifugal force to reliably throw out the blades. The maximum speed of the small-displacement double-acting quantitative vane pump is 8000-10000r/min, but the general product is only 1500-2000r/min, which is generally lower than the gear pump.

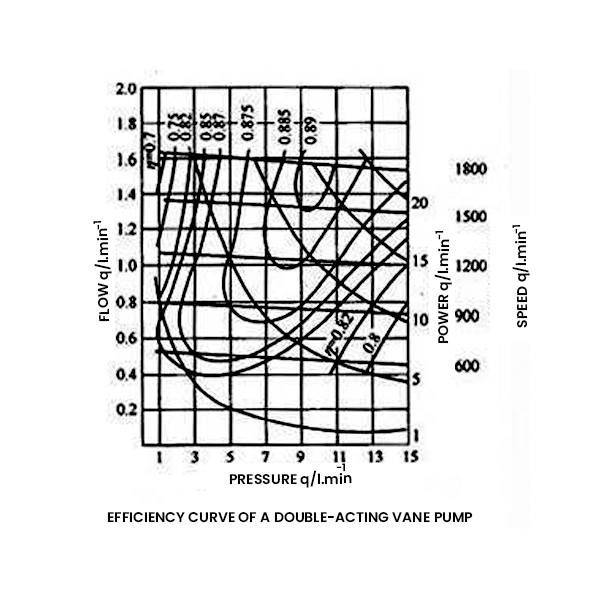

(4) Efficiency The volumetric efficiency of a single-acting quantitative vane pump can reach 92% under rated working conditions; the volumetric efficiency of a double-acting quantitative vane pump can exceed 94% under rated working conditions, which are slightly lower than gear pumps, but vane pumps The mechanical efficiency is generally higher. Therefore, the overall efficiency of the two is almost the same. The figure below shows the efficiency curve of a double acting vane pump.

Vane Pump Efficiency Curve

(5) Life expectancy Due to the small load on the bearing and the balance of force on the distribution plate, the service life of the high-pressure vane pump is generally longer than that of the gear pump, which can reach more than 5000h.

(6) Noise The noise of the single-acting variable vane pump is relatively high, only slightly lower than that of the variable piston pump. The noise of the double-acting quantitative vane pump is very low, which is comparable to that of the internal gear pump.

(7) Power density Since the double-acting vane pump has a larger working volume per unit structural volume (the "double-acting" feature), it may be smaller in size than the gear pump when the displacement is the same; but the latter may The operating pressure and speed are relatively high, and the external gear pumps mostly use aluminum alloy casings, so the gear pumps are still dominant in terms of power density.

(8) Main structural parameters For double-acting quantitative vane pumps, the ratio of the large and small radii of the stator slideway surface is generally R/r=1.06~1.15. Increasing the width B of the rotor and stator can reduce the proportion of the leakage along the end surface to the total output flow, which is beneficial to improve the volumetric efficiency, but if the B value is too large, the flow rate in the distribution window will be too high and the pressure loss will increase. For single-acting pumps It will also deteriorate the bearing stress, generally B/r=0.45~1. For example, YB series vane pump with a flow rate of 25-200L/min B=20-40mm. The eccentricity of the single-acting pump is generally e/D=0.025~0.03.

The minimum number of blades (should be an even number) that satisfies the sealing conditions of the separated working volume is Zmin=6. Considering the strength of the rotor, the number of blades should be less. The shape of the segment matches, generally 2=8~18, and Z=10 and 12 are the most. In order to reduce the flow pulsation, the number of blades of the single-acting pump should be an odd number (Z=9~21 is often taken).

The thickness of the blade should be as thin as possible under the premise of meeting the strength requirements and process possibility, generally b=1.8~2.5mm. For example, the vane thickness of YB series vane pump with a flow rate of 12-200L/min is b=2.25mm.

The backward tilt angle of the single-acting vane pump is generally θ=0°~24°. The vane forward angle of the double-acting vane pump is usually θ=0°~14°. For example, the blade forward angle of the YB series vane pump with a flow rate of 10-100L/min is θ-13°.