Cause Analysis of AC Electromagnet Noise in Electromagnetic Reversing Valve

During the use of the electromagnet of the electromagnetic reversing valve, two kinds of noises often appear, namely "click, click, click..." and "hum, buzz, buzz...". The reasons are analyzed and eliminated as follows.

1. Reason analysis

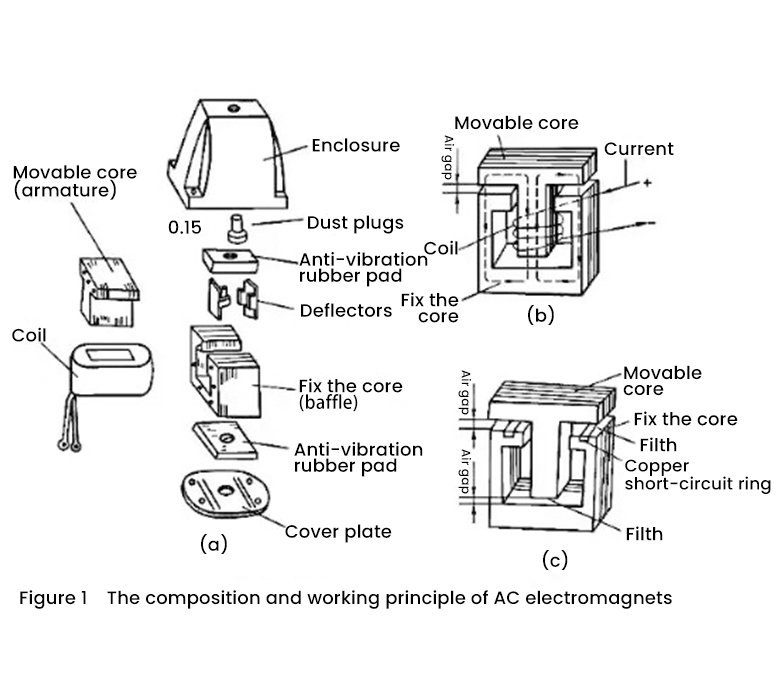

① The quality of the electromagnet itself is faulty. The components of the AC electromagnet are shown in Figure 1 (a). When the coil is energized, a magnetic circuit is formed between the movable iron core and the fixed iron core to generate attraction force, as shown in Figure 1 (b). When the guide plate and the movable iron core are poorly processed and assembled, or the processing of the movable iron core and the fixed iron core is wrong, the fixed iron core and the movable iron core cannot be well attracted and cry.

②The air gap between the movable iron core and the fixed iron core has fallen red lead anti-rust paint flakes and other dirt stuck, which cannot be well absorbed, resulting in a "hum, hum, hum..." air gap sound, as shown in Figure 1(c).

③ The copper short-circuit ring on the fixed electromagnet breaks, producing electromagnetic sound and vibration sound.

④The force of the return spring is too large, exceeding the suction force of the electromagnet. When the power is turned on, there will be a "click, click, click..." noise.

⑤ There are problems with the burr and matching precision between the valve core and the valve hole, the friction force is too large, exceeding the suction force of the electromagnet, or the core is stuck due to dirt, the electromagnet cannot be pushed, and "hum, weng, weng" is often emitted. ..." noise.

⑥The push rod is too long, so that the movable iron core and the fixed iron core cannot be well attracted to maintain a normal air gap, resulting in noise. At this time, it is "click, click, click..." noise.

2. Troubleshooting

① Check the quality of the electromagnet and whether the assembly is good, and solve the problem in time or replace the electromagnet if it is found.

② Check the air gap between the movable iron core and the fixed iron core to see if there are falling red lead anti-rust paint flakes and other dirt, and clean up the fallen off in the air gap between the movable iron core and the fixed iron core in time. Red lead antirust paint flakes and other dirt.

③ Replace the electromagnet with a new one.

④ Replace the return spring that meets the requirements.

⑤ Check and grind the valve core and valve hole to restore the original precision; check and clean the dirt.

⑥Appropriate grinding to shorten the length of the push rod. It should be noted that the opening of the valve core may be affected after the push rod is shortened. It must be considered comprehensively, and it should not be worn too short, so as not to cause poor commutation failure. In addition, the same type of electromagnets from different electromagnet manufacturers often require different lengths of push rods.