How does the vane pump work?

The structure of the vane pump is more complicated than that of the gear pump. It has higher working pressure, less flow pulsation, stable operation, lower noise and longer life, so it is widely used in medium and low pressure hydraulic systems such as special machine tools and automatic lines in machinery manufacturing.

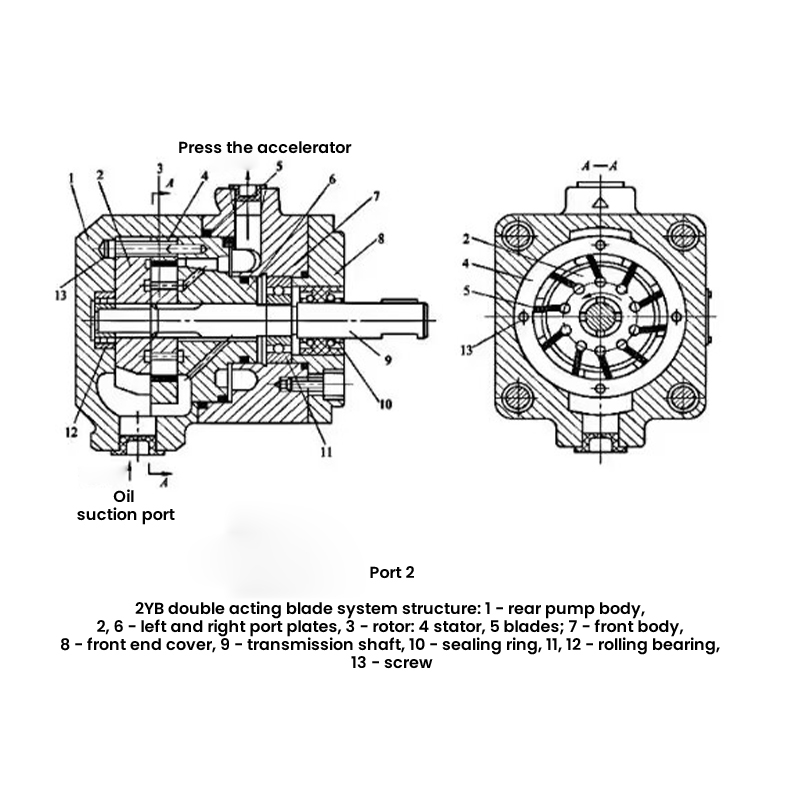

However, its structure is complex, its oil absorption properties are not very good, and it is also sensitive to oil pollution. According to the difference in suction and discharge times of each sealed working volume in the rotation cycle of the rotor, the vane pump is divided into two types, namely, the single-acting vane pump that completes one suction and discharge of oil, and the double-acting vane pump that completes two suction and discharge of oil Pumps, single-acting vane pumps are mostly used for variable displacement pumps, the maximum working pressure is 7.0MPa, double-acting vane pumps are quantitative pumps, generally the maximum working pressure is also 7.0MPa, and the maximum working pressure of the high-pressure vane pump with improved structure can reach 16.0- 21.0MPa.

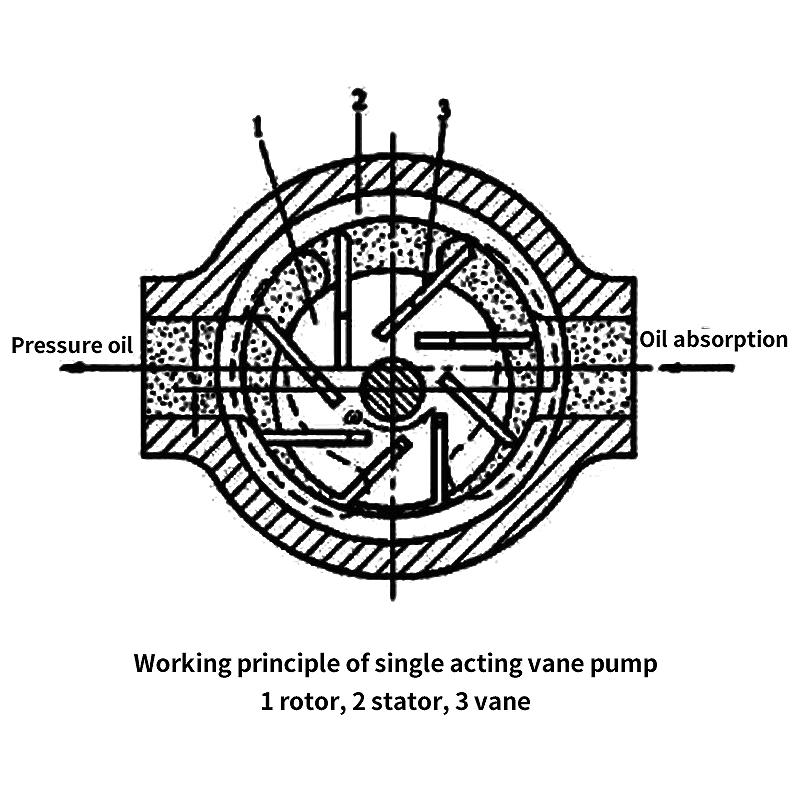

The vane pump works like this, as shown in the figure below, it is composed of rotor 1, stator 2, vane 3 and end cover. The stator has a cylindrical inner surface, and there is an eccentric distance e between the stator and the rotor. The blades are installed in the rotor groove and can slide in the groove. When the rotor rotates, due to the centrifugal force, the blades are close to the inner wall of the stator, so that Several sealed working spaces are formed between the rotor, blades and the oil distribution plates on both sides.

When the rotor rotates in the direction shown in the figure, the blades are gradually stretched out in the right part of the figure, and the working space between the blades gradually increases, and oil is sucked from the oil suction port, which is the oil suction chamber. In the left part of the figure, the vane is gradually pressed into the vane slot by the inner wall of the stator, and the working space is gradually reduced. The oil pressure chamber is formed by pressing the oil out from the oil pressure port. There is an oil sealing area between the oil suction chamber and the oil pressure chamber, which separates the oil suction chamber from the oil pressure chamber. This kind of vane pump rotor completes one revolution of oil suction and oil pressure in each working space, so it is called single-acting vane pump. The rotor is constantly rotating, and the pump is constantly sucking and discharging liquid.