【Hydraulic knowledge】Structure, working principle and flow factors of quantitative pump and variable pump (2)

2.variable vane pump structure, working principle, flow factors

(1)Structure of variable vane pump

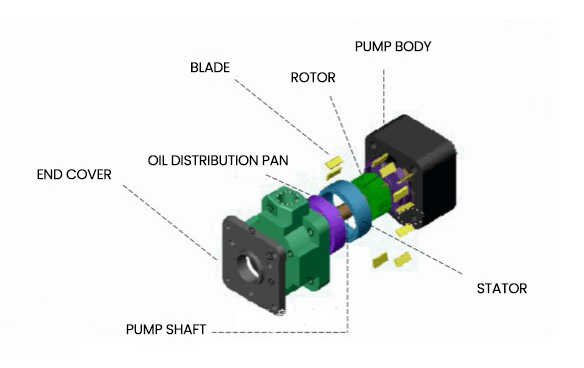

From the appearance, the components of the single-acting vane pump include the pump shaft end cover, and the pump body. The inside of the pump body is composed of a stator, a rotor, blades and an oil distribution plate. There are blade grooves on the rotor, and the blades are placed in the blade grooves. It can slide freely in the radial direction in the groove. Two oil distribution plates are respectively installed at both ends of the stator and the rotor. When the power is input from the pump shaft to drive the rotor to rotate, oil can be sucked and pressed.

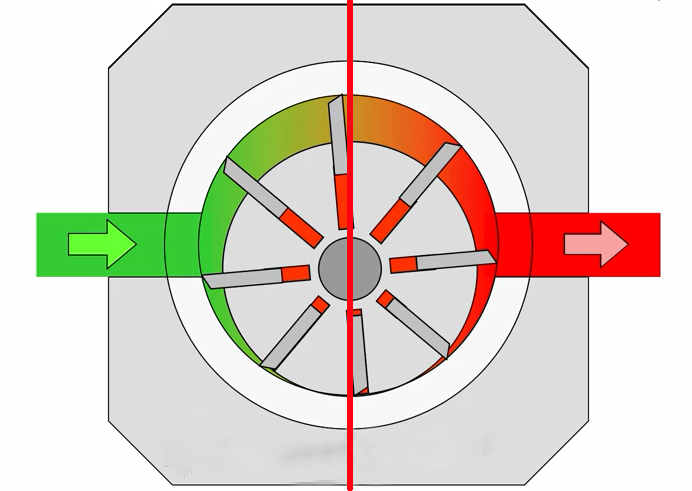

In the specific process of oil absorption and oil pressure, the curves of the inner surface of the stator and the outer surface of the rotor are circular, and the stator and the rotor are installed eccentrically, so the distance between the inner surface of the stator and the outer surface of the rotor is constantly changing.

(2)Working principle of variable vane pump

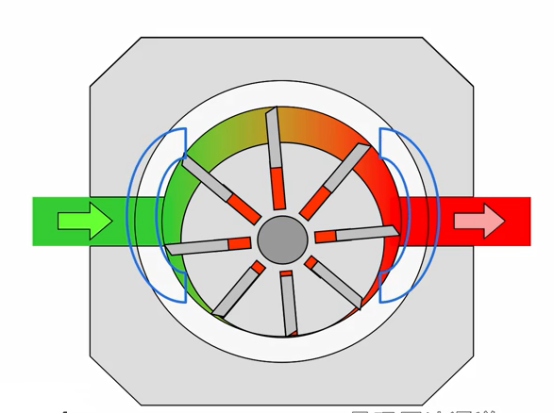

The separation limit is the line connecting the two centers, the rotor rotates clockwise, in the area on the left side of the line connecting the centers, the distance between the stator and the rotor increases continuously, the blades protrude, and the space volume formed between two adjacent blades When the oil pressure increases, the oil pressure decreases. Under the action of the external atmospheric pressure, the oil in the oil tank enters the pump from the oil suction port, and connects the right side area at the center of the circle. The distance between the stator and the rotor decreases continuously, and the blades retract. The volume of the space formed between adjacent blades decreases, the oil pressure rises, and the high-pressure oil is output through the oil pressure port. Therefore, the left half is the oil suction area, and the right half is the oil pressure area. The rotor rotates once to complete a complete oil suction process, so it is called a single-acting vane pump

Note that because of the waist hole on the oil distribution plate, it is a suction oil channel. Therefore, its position must correspond to the oil suction area and the oil pressure area respectively.

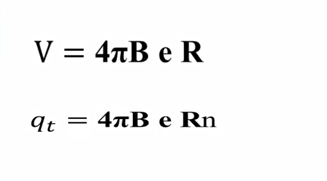

(3)Factors related to displacement and flow of variable vane pump

B is the width of the blade, and e is the eccentricity. It can be seen that the displacement of the pump can be changed by changing the size of the centering distance e without changing the size of the parts. This kind of hydraulic pump with adjustable displacement is called a variable pump. When the eccentric distance increases, the flow rate increases, and when the eccentric distance decreases, the flow rate decreases. When the eccentric distance is 0, the flow rate is 0. Because one side of the single-acting vane pump is the oil suction area, the pressure is low, and the other side is the oil pressure area, the pressure is high. Therefore, it is affected by radial unbalanced force, which is also a factor that limits its pressure increase.