Instructions for use of the vane pump

Vane pumps are used in a wide range, pay attention to steering, pressure, oil viscosity, etc. when using them.

(1) Check the steering, speed range, pressure, temperature, and working quality and viscosity of the vane pump. If the oil viscosity is too high, the vane cannot slide out of the rotor groove due to the large sliding resistance, so as to replace the lower viscosity of the oil; before cold weather Use hot oil first, remove the oil drain if necessary, and fill the pump with oil before turning it on;

(2) Check whether the condition of the oil suction port of the vane pump meets the working requirements;

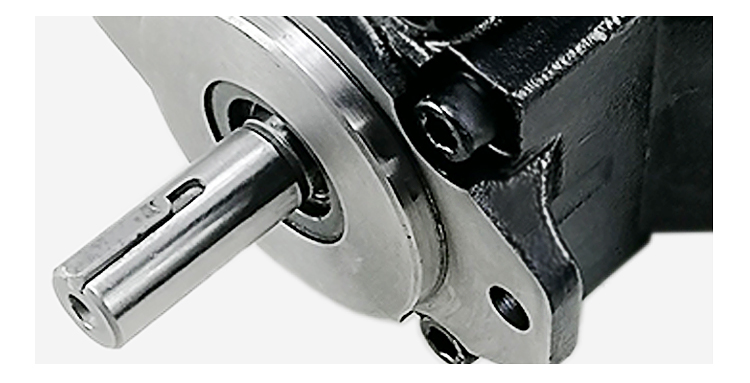

(3) Check whether the drive shaft type of the vane pump meets the working torque requirements;

(4) The selected vane pump coupling must be able to minimize the load on the transmission shaft (reset, coaxiality);

(5) The filter measures adopted must ensure that the oil meets the cleanliness requirements. During the commissioning and continuous use, the oil filter should be used to clean the working oil, and the solid particle pollution of the oil should not be higher than NAS 1618 level 8 or ISO Class 18/14;

(6) The operating environment of T6 series vane pumps should avoid noise, pollution and vibration;