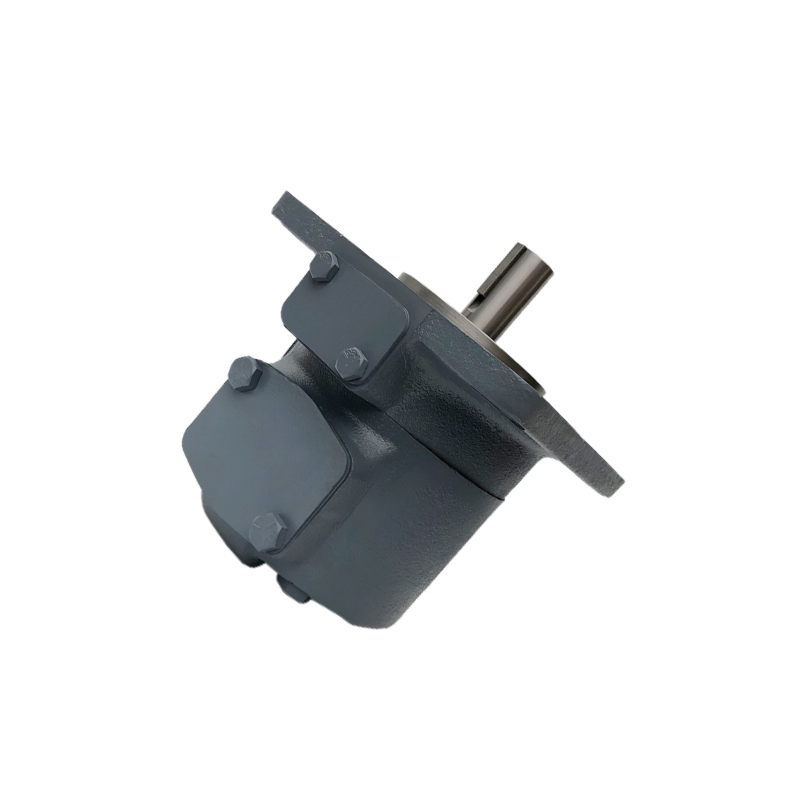

V series vane pump explanation

Performance

This cost-effective pump offers over 90% volumetric efficiency and a low 62 dB(A) sound level at an operating pressure of 210 bar (3000 psi). Repair-in-place with pump cartridge replacement reduces downtime and increases productivity.

general description

Dual vane pumps offer long life, high productivity and application flexibility. The extremely low noise level suits the most demanding industrial applications. Compact size and ease of use allow maximum flexibility in equipment design. Single pumps, double pumps and thru drive pumps are available.

Features and Benefits

The ability to achieve high operating pressures in a compact form factor ensures a high power-to-weight ratio with reduced installation costs. The inherent low-noise characteristics of the parent-child blade mechanism improve the operator's comfort. The 12-blade system ensures that the amplitude of flow pulsation is small and the system noise characteristics are low. Hydraulic balancing designed to prevent internally induced radial loads on the shaft and bearings ensures long life.

Management points of vane pump

The vane pump is a pump in which the vanes in the rotor slot are in contact with the pump casing (stator ring), and the sucked liquid is pressed from the oil inlet side to the oil discharge side. The main points of vane pump management are to prevent dry running and overload, prevent air inhalation and excessive suction vacuum, and also pay attention to: If the direction of pump rotation changes, its suction and discharge direction will also change. . Because the rotor blade grooves are inclined, the blades are chamfered, and the bottom of the blades communicates with the oil discharge chamber, the throttle groove and suction and discharge ports on the oil distribution plate are designed according to the established rotation. Small pump - 0.015 ~ 0.03mm Medium pump - 0.02 ~ 0.045mm The temperature and viscosity of the oil should generally not exceed 55 ℃, and the viscosity should be between 17 ~ 37mm2/s. If the viscosity is too high, it will be difficult to absorb oil; if the viscosity is too small, the leakage will be serious. Reversible vane pumps must be specially designed. The vane pump assembly oil distribution plate and the stator are correctly positioned with the positioning pins. The vane, rotor, and oil distribution plate must not be installed upside down. The suction area of the inner surface of the stator is the most prone to wear. Continue to use for drain area.

Vane pump disassembly

Disassembly and assembly Pay attention to the cleanliness of the working surface, and the oil should be well filtered during work. If the gap between the blades in the leaf groove is too large, the leakage will increase, and if it is too small, the blades will not be able to expand and contract freely, which will lead to malfunction. The axial clearance of the vane pump has a great influence on ηv.