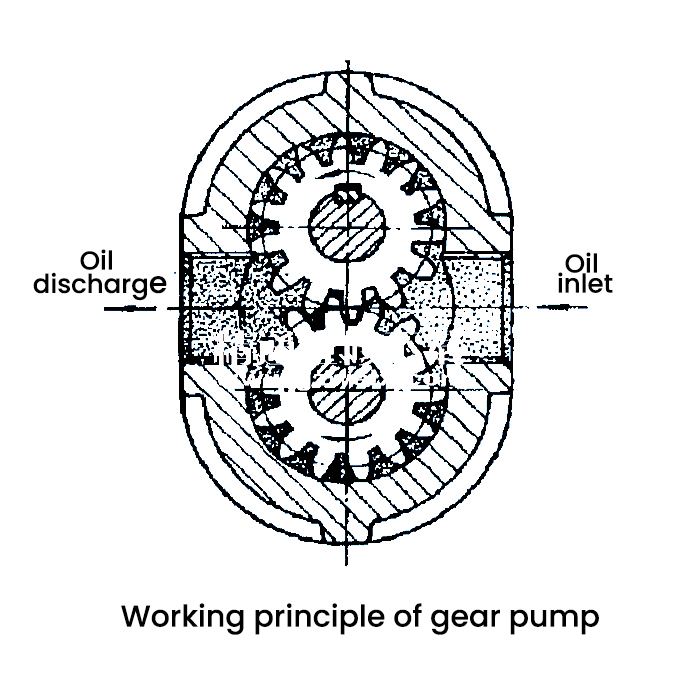

Working principle of hydraulic gear pump

1. The working principle of the hydraulic gear pump is that when the gear rotates, the volume of the space on the gear disengagement side increases from small to large, forming a vacuum to suck the liquid, and the volume of the space on the meshing side of the gear changes from large to small, and squeezes the liquid into the pipeline to go.

2. In terms of terminology, a gear pump is also called a positive displacement device, that is, like a piston in a cylinder, when one tooth enters the fluid space of another tooth, because the liquid is incompressible, the liquid and the tooth cannot Occupy the same space at the same time, so that the liquid is mechanically squeezed out.

3. Due to the continuous meshing of the teeth, this phenomenon occurs continuously, so a continuous discharge volume is provided at the outlet of the pump, and the discharge volume is the same every time the pump rotates. As the drive shaft rotates continuously, the pump discharges fluid continuously. The flow rate of the pump is directly related to the speed of the pump.

4. In fact, there is a small amount of fluid loss in the pump, because these fluids are used to lubricate both sides of the bearings and gears, and the pump body can never fit without clearance, so the fluid cannot be discharged from the outlet 100% , so a small amount of fluid loss is inevitable, which prevents the pump from operating at 100%.

5. However, the pump can still run well, and it can still reach an efficiency of 93% to 98% for most extruded materials.