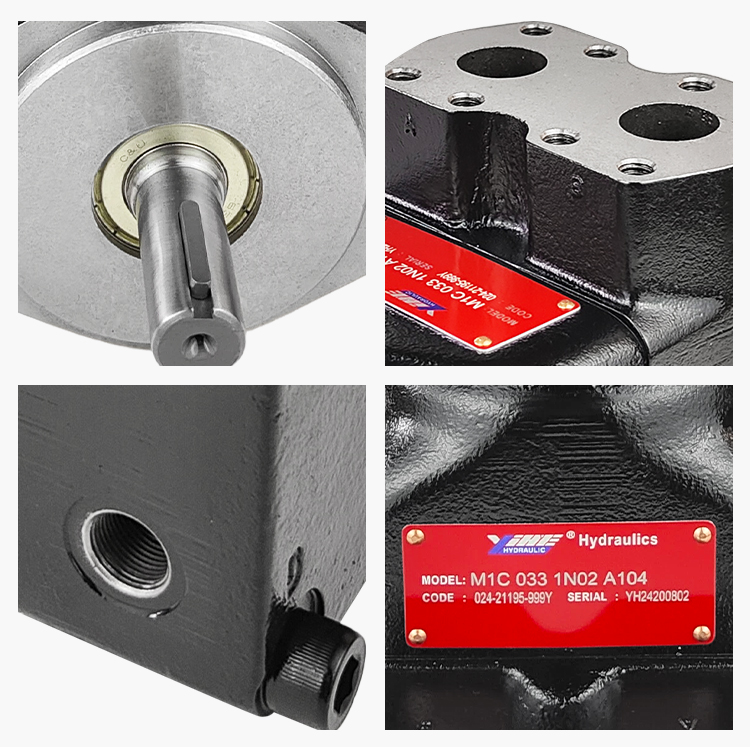

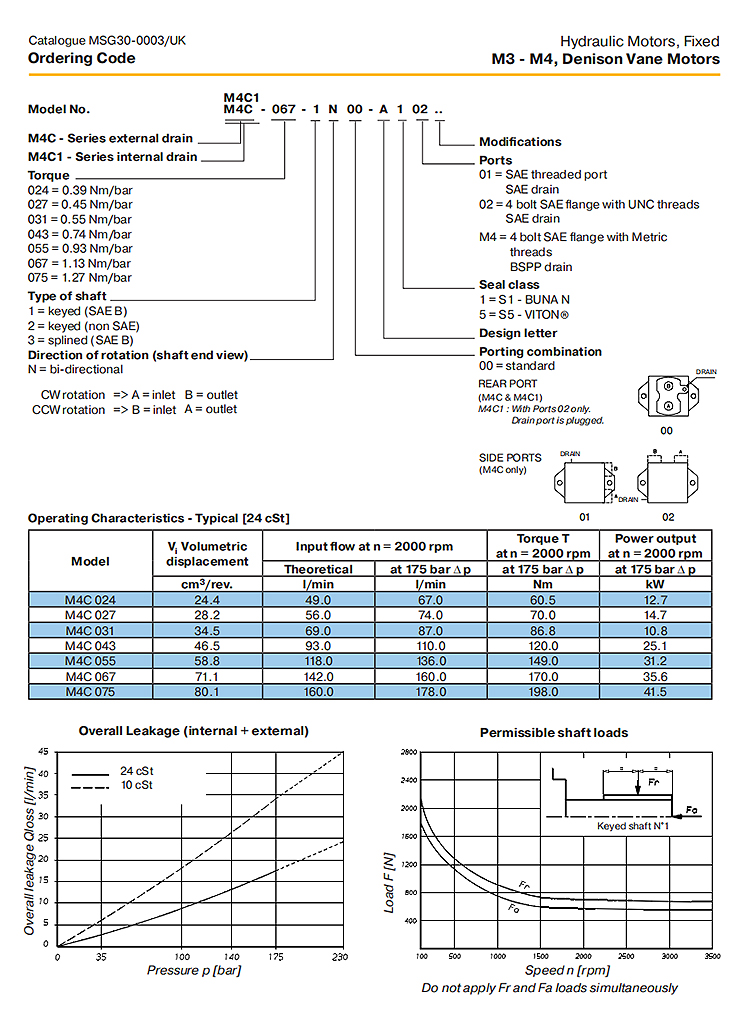

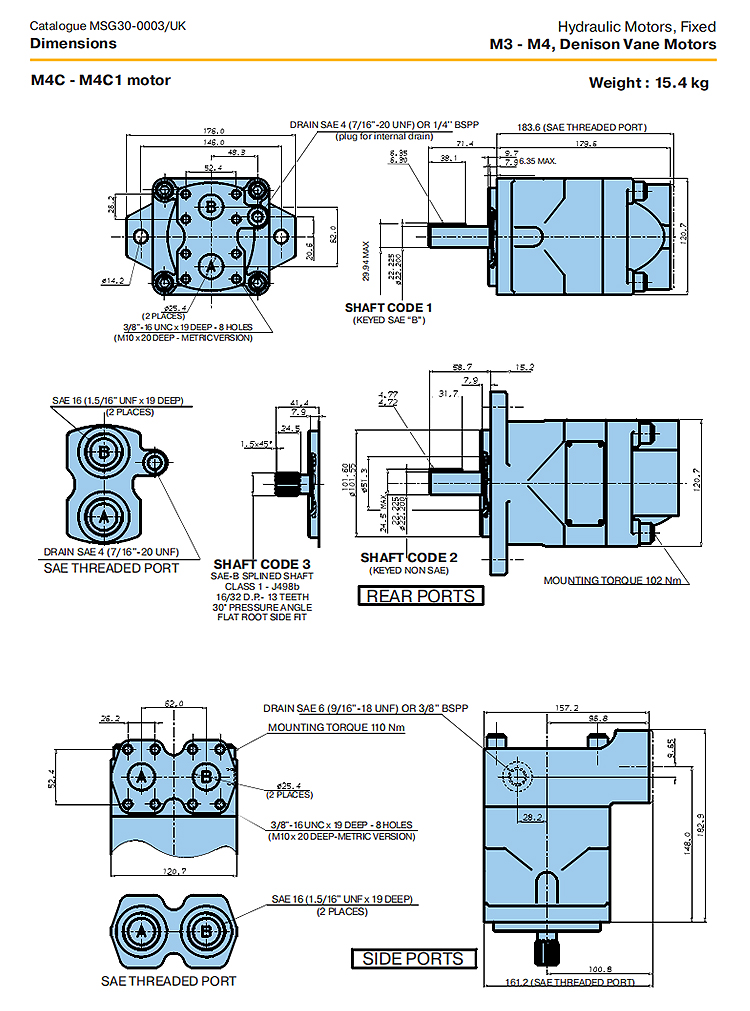

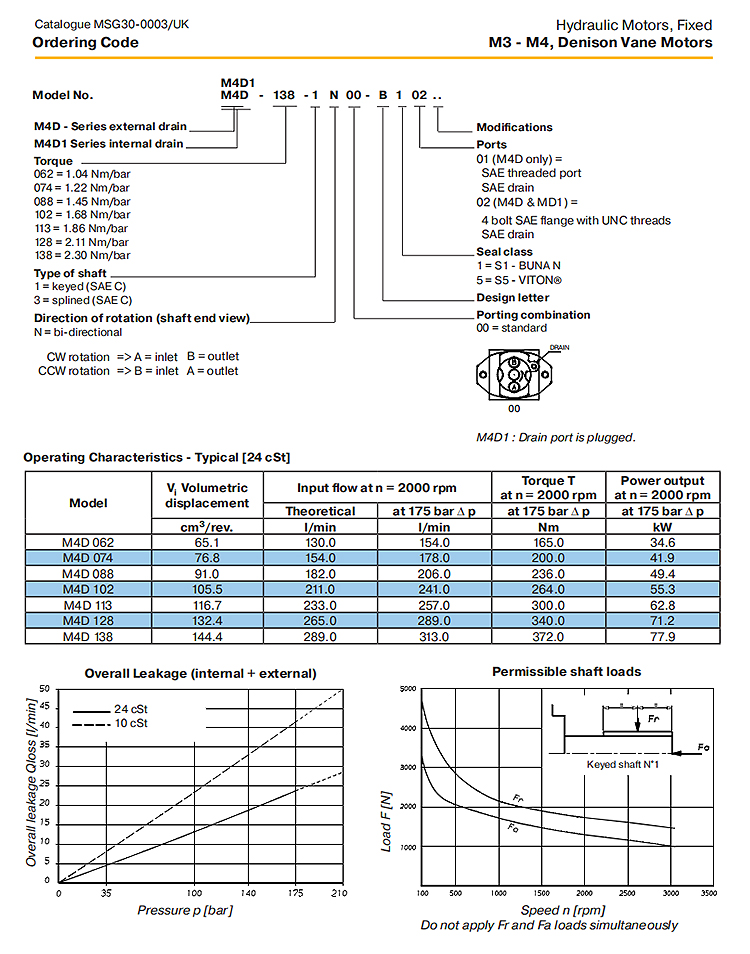

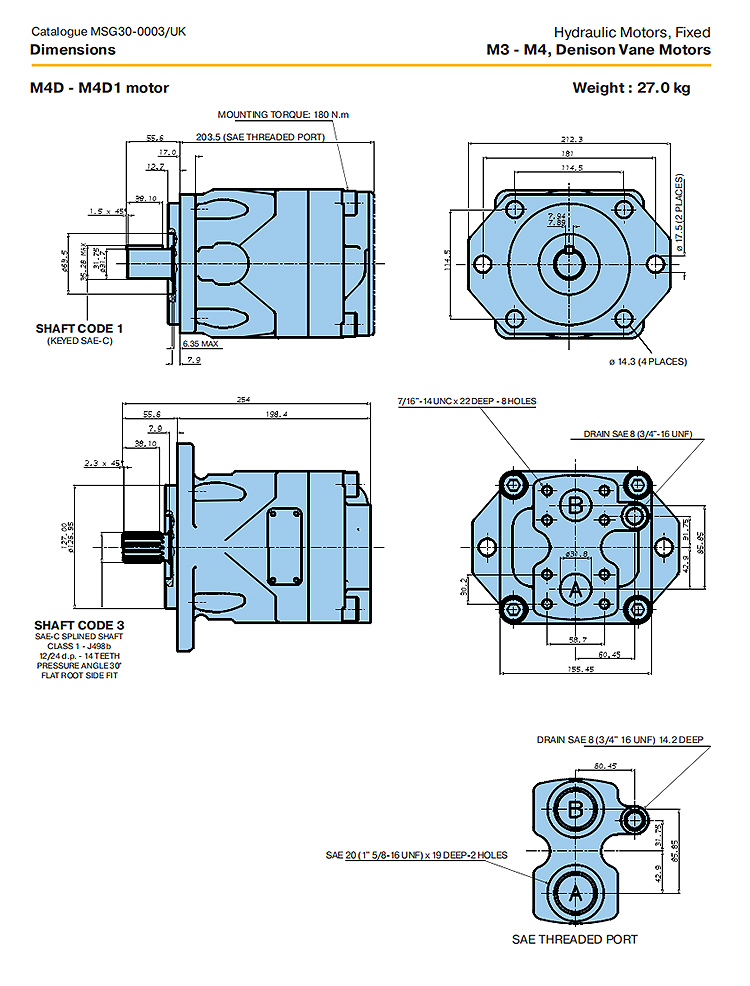

denison vane motor hydraulic M1C-033-1N00-A102 M1C-042-1N00-A102 hydraulic motor price M1C-052-1N00-A102 parker hydraulic motor

Brand: YIHE

Product origin: China

Delivery time: 2-3days

Supply capacity: 300pcs/day

Model: M1C

Material: Cast iron

Delivery time: 2-3

Starting batch: 1 set

Place of shipment: China

Pump type: Vane motor

Product Details

The main structural differences between vane motors and vane pumps are:

(1) Motors must have aane pressing mechanism to ensure that the vanes are in tight contact with the inner surface of the stator before startup, otherwise, they cannot start.

(2) Pumps only need to rotate in one direction, while motors need to rotate both forward and backward.

Therefore, the vanes of the motor are all radially, with symmetrical top ends; the two main oil ports have the same diameter; the oil drainage for bearing lubrication has a separate oil return pipe when necessaryfor motors specifically used in lifting mechanisms, the oil drainage from the bearings can be internally connected to a fixed low-pressure chamber; the vane roots can communicate with pressure oil chamber regardless of whether the motor is rotating forward or backward. After equipping a multi-acting vane motor with a shift valve, it can manually automatically change the number of effective working chambers based on working pressure, i.e., let one or several pairs of inlet and outlet oil chambers communicate with each other without oil supply, so there is no oil pressure difference between them and no torque is generated, thus becoming a step-variable motor with variable displacement. When the three- motor becomes single or double-acting, the radial forces are unbalanced, so it is only suitable for low pressure; when the medium and high-pressure vane are variable, they should always maintain radial force balance, and are often made into four or six-acting motors.

The vane pressing mechanisms commonly used in v motors are as follows:

(1) Straight rod mechanism--At the bottom of each pair of vanes in relative positions around the circumference, two straight rods passing the rotor axis are used to maintain the seal between the vanes and the stator surface, while introducing the working oil from the pressure side into the small oil at the bottom of each vane to help press the vanes outward. In bidirectional motors, the oil passages to the vane bottoms are equipped with shuttle to ensure that the working oil from the pressure side can be introduced to the vane bottoms whether rotating forward or backward.

(2) Arcuate rod--Severaluate rod grooves are opened on the two end faces of the rotor, with the intersecting parts of each pair of arcuate rods having a reduced cross-section and drill holes at both ends of the rods, with compensation springs inside, to press the vanes against the stator surface.

(3) Rocker arm rod--Rocker arms are installed on both end faces of the rotor, which maintain the initial seal of each pair of vanes through rods and compensation springs.

(4) Springs are set at the bottom of the vanes.

Compared with plunger motors, vane motors have a simpler structure and the lightest weight per displacement, but their volumetric efficiency is lower, and they are only suitable for medium and low pressures. Moreover, the friction between the vane tips and the surface of the stator is relatively high, resulting in lower mechanical efficiency and starting efficiency, and poorer low-speed stability

Company Profile

01. Factory direct price

02. Brand new product, better quality

03. Fast delivery within 2 days

04. Accept OEM

05. Customized products

06. No minimum order quantity, 1 piece is enough. Small orders are welcome

07. Support online payment or other payment methods

08. 24-hour after-sales service

09. Two major production plants

10. Export to 150 countries

Guangzhou Yisheng Machinery Equipment

We are Guangzhou Yisheng Machinery Equipment Co.,Ltd., which located in Foshan City, Guangdong Province, China. We have R&D department with about 5-10 engineers and designers. Our factory have over 100 skilled employees, our production facility have many advanced manufacturing equipments and testing equipments, such as numerical control lathe, the processing center, CNC milling machine, special CNC grinding machine, double grinding machine, automatic 3D measuring instrument, etc..

Our main products are hydraulic variable displacement vane pump, double pump, HVP high pressure variable displacement vane pump, PV2R1 & PV2R2 series,V&VQ series,T6&T7 series, SQP series and VQ series of fixed displacement vane pump and electrical motors for hydraulic application.

Our products are widely used for industrial machinery, NC lathe machine, shoe machinery, wood working machines, plastic machines, construction machines and various hydraulic system machinery. We also able to supply the customized products and services as per your spec. ,we are looking forward to cooperating with your company sincerely.

1.Frequent Visitor To International Hydraulic Exhibitions

Our company participates in major international hydraulic exhibitions every year and communicates with customers in the hydraulic industry

2. Perfect Service

Professional customer service staff, each of whom has more than five years of hydraulic experience, provide one-on-one service and

provide you with hydraulic solutions.

3.Quality assurance, 100% brand new products

We guarantee that all products are brand new. We will not sell second-hand refurbished products, nor will we sell inferior products. Because we are a professional factory, we have sufficient spot inventory, which can greatly shorten the delivery time.

FAQ

Q: Are you trading company or manufacture?

A: We are factory

Q: How long is your delivery time?

A: Gernally it is 1-2days if the goods are in stock.It is 5-7days if the goods no stock.It is subject to order quantity.

Q: Do you provide sample,Is it free or extra?

A: We are willing to provide samples to test quality first, it is not for free because it is high value products. But sample cost can return in bulk order.

Q: What is the terms of payment?

A: 100% deposit or 30% deposit, 70% before shippment.

Q: How long is the warranty?

A: We offer 12 months warranty.