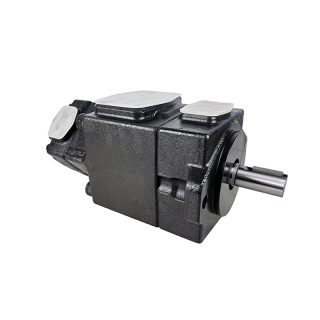

Marine hydraulic vane pump T6EE-072-062-2R00-A10M0 high pressure servo crane oil pump T6EE-066-052-2L03

Brand: YIHE

Product origin: China

Delivery time: 3 days

Supply capacity: 300 pcs/day

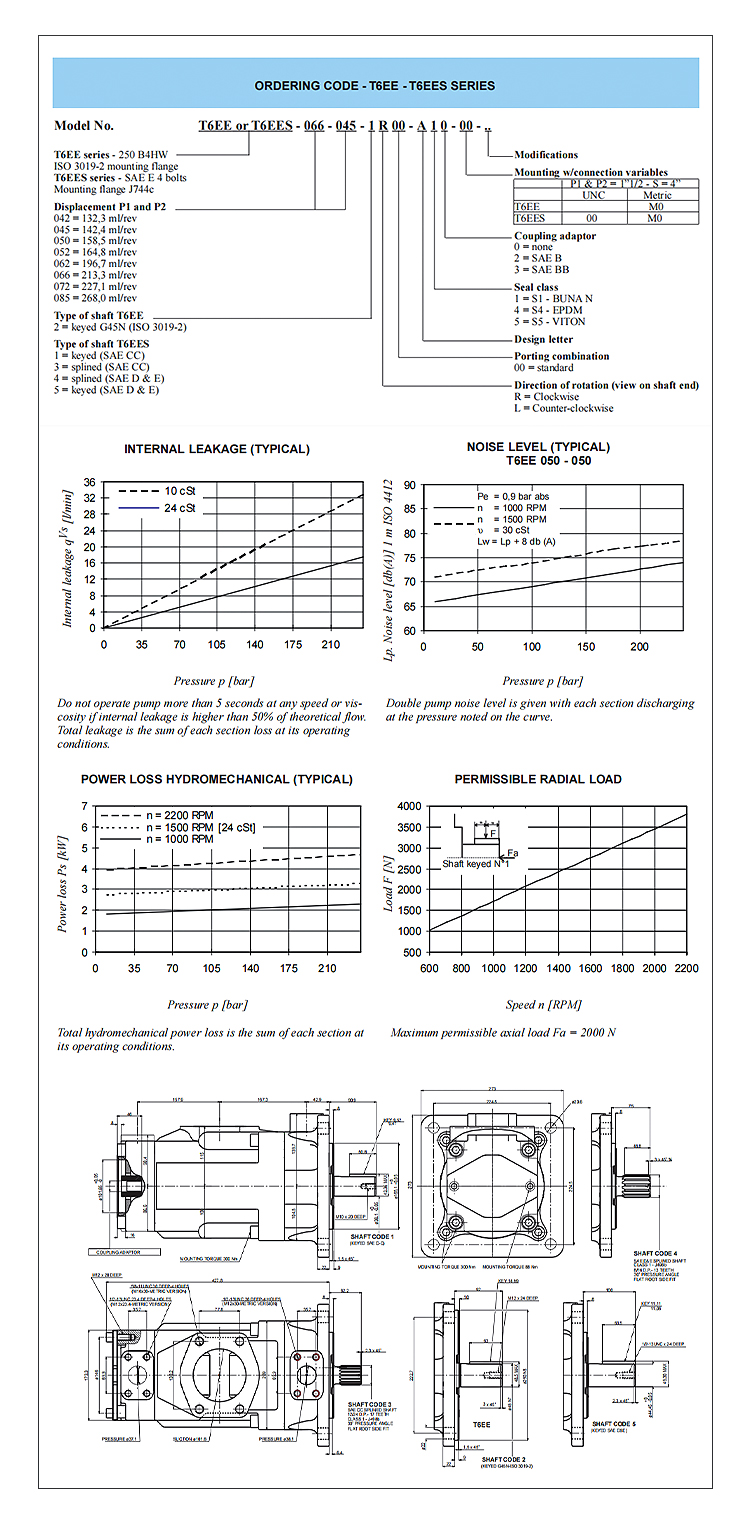

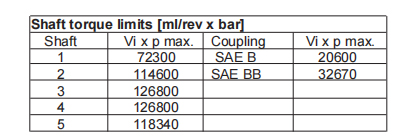

Displacement: 132.3-269 ml/rev

Speed range: 600-2200 rpm

Type: Double vane pump

Maximum working pressure (intermittent): 120-240 bar

Maximum working pressure (continuous): 80-210 bar

Specifications: 042/045/050/052/057/062/066/072/085

Weight: 95 kg

Applications: Injection molding machinery, hydraulic machinery, engineering machinery, construction machinery, machine tool machinery, marine machinery, mining machinery

Product details & parameters

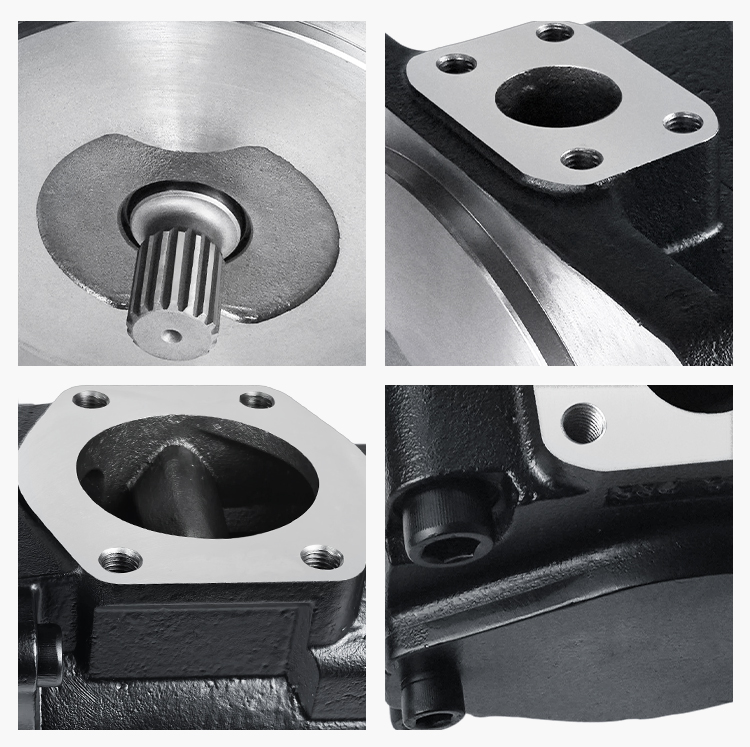

1. The maximum working pressure of T6 series single vane pump is optional from 190bar to 320bar.

2. Maximum displacement is optional from 40ml/rev to 269ml/rev

3. Pump weight from 7.0Kg to 66Kg

4. This series of vane pumps are mainly used in industrial and mobile machinery

5. It has the advantages of complete high, medium and low voltage, low noise, long service life, easy maintenance and high efficiency.

Company profile & advantages

Guangdong Yihe Hydraulic Technology Co., Ltd.

We are Guangzhou Yisheng Machinery Equipment Co.,Ltd., which located in Foshan City, Guangdong Province, China. We have R&D department with about 5-10 engineers and designers. Our factory have over 100 skilled employees, our production facility have many advanced manufacturing equipments and testing equipments, such as numerical control lathe, the processing center, CNC milling machine, special CNC grinding machine, double grinding machine, automatic 3D measuring instrument, etc..

Our main products are hydraulic variable displacement vane pump, double pump, HVP high pressure variable displacement vane pump, PV2R1 & PV2R2 series,V&VQ series,T6&T7 series, SQP series and VQ series of fixed displacement vane pump and electrical motors for hydraulic application.

Our products are widely used for industrial machinery, NC lathe machine, shoe machinery, wood working machines, plastic machines, construction machines and various hydraulic system machinery. We also able to supply the customized products and services as per your spec. ,we are looking forward to cooperating with your company sincerely.

Instructions for use

To protect your rights please read the following carefully

Pump Start-up Procedure

Preparation Prior to Start-up

The reservoir and circuit should be clean and free of dirt and debris prior to filling with fluid.

Circuit Cleanup

The reservoir should be charged with filtered hydraulic fluid. The fluid level should be sufficient to prevent vortexing at the suction connection to the pump inlet. It is good practice to clean the system by flushing and filtering, using an external slave pump.

Filling Pump and Removing Air

If the pump is mounted above the fluid level, it should be filled with fluid through the outlet port. If the pump is mounted below the fluid level, the pump outlet fitting (or other downstream fitting or plug) can be loosened to allow fluid to displace the air. It may be necessary to loosen the fill cap on the reservoir to allow the fluid to flow freely. When a solid stream of fluid with no observed air begins to drain through the loosened fitting, the fitting should be retightened. An air bleed valve in the outlet circuit is also recommended to remove trapped air. If such a device is used, the pump should be filled with fluid before start-up. In some cases, it may be possible to prime the pump by running the engine starter for five to ten seconds with the throttle and/or ignition switch in the "off" position. It will be necessary to loosen a fitting or plug in the pump outlet to allow air to escape.

Pump Start-up

All controls should be placed in the neutral position so the pump is unloaded when started. Start the engine and run at low idle. Once the pump is started, it should prime and pump within a few seconds. If it does not, make sure there are no restrictions between the reservoir and the inlet to the pump, and that there are no air leaks in the inlet line and connections. Also, make sure that trapped air can escape from the outlet. Run at low engine idle for approximately five minutes. Then, while observing the reservoir fluid level, operate the implements. Extend all actuators to maximum safe limits to completely fill the system with fluid. Do not run with the fluid level below the "low" limit. Add fluid to the reservoir to bring the fluid to the proper fill level.

FAQ

Q1:Can you ship the goods to our country?

A:Yes, you can choose express (DHL/UPS/FEDEX/EMS/ARAMEX/TNT) and by air, by sea to most countries.

Q2:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q3: Are you trading company or manufacture?

A: We are factory

Q4: How long is your delivery time?

A: Gernally it is 1-2days if the goods are in stock.It is 5-7days if the goods no stock.It is subject to order quantity.

Q5: Do you provide sample,Is it free or extra?

A: We are willing to provide samples to test quality first, it is not for free because it is high value products. But sample cost can return in bulk order.

Q6: What is the terms of payment?

A: 100% deposit or 30% deposit, 70% before shippment.

Q7: How long is the warranty?

A: We offer 12 months warranty.

Q8:How do you make our business long term and good relationship?

A:1. We will ensure the interests of our customers with good quality and competitive price;

2. We treat every customer as a friend and sincerely do business with everyone and make friends, no matter where they are from.