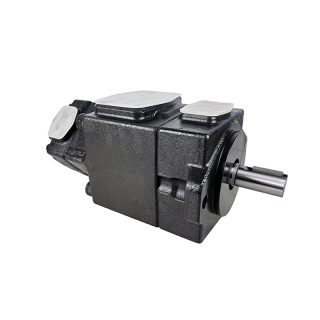

YIHE Type T6CC T6DC T6EC T6ED Hydraulic Vane Pump high pressur pump

Brand: YiHe

Product origin: China

Delivery time: 10-30day

Supply capacity: 300 Pcs/Day

Model: T6CC T6DC T6EC T6ED

Max Displacement: 10.8 ml/rev - 269ml/rev

Max Working Pressure: 80 Mpa- 24 Mpa

Shaft Speed Range: 600 r/min - 2800 r/min

Rotation: Right and Left From Shaft End

Control Type: DOSING PUMP

Product Type: Vane Pump

Model Quick Navigation

product information

| Brand | YIHE | Series | T6CC T6DC T6EC T6ED |

| Model | T6CC T6DC T6EC T6ED | Product type | Double vane pump |

| Delivery time | 10-30day | Warranty period | 365 day |

| Material | cast iron | Supply capacity | 300 Pcs/Day |

| Product origin | China | Max Displacement | 10.8 ml/rev - 269ml/rev |

| Max Working Pressure | 80 Mpa- 24 Mpa | Shaft Speed Rang | 600-2500 r/min 600-2800 r/min |

Show details

Powerful and fast

Low noise and low heat

Strong performance and high efficiency

Professional design, wear-resistant and pressure-resistant

Company Profile

We are Guangdong Yihe Hydraulic Technology Co., Ltd., located in Foshan City, Guangdong Province, China. We have a R&D department of about 5-10 engineers and designers. The factory has more than 100 skilled employees, and the production equipment has advanced manufacturing equipment and testing equipment such as CNC lathes, machining centers, CNC milling machines, special CNC grinding machines, double grinding machines, and automatic 3D measuring instruments.

The main products are hydraulic variable vane pump, duplex pump, HVP high pressure variable vane pump, Yuken type PV2R1&PV2R2 series, Vickers type V&VQ series, Parker Denison T6&T7 series, Tokimec type SQP series and KCL type VQ series fixed exhaust for hydraulic applications. Volume vane pump and electric motor.

Our products are widely used in industrial machinery, CNC lathes, shoe machines, woodworking machinery, plastic machinery, construction machinery and various hydraulic system machinery. We are also able to provide customized products and services according to your specifications. , We look forward to sincere cooperation with your company.

Instructions for use

To protect your rights please read the following carefully

Pump Start-up Procedure

Preparation Prior to Start-up

The reservoir and circuit should be clean and free of dirt and debris prior to filling with fluid.

Circuit Cleanup

The reservoir should be charged with filtered hydraulic fluid. The fluid level should be sufficient to prevent vortexing at the suction connection to the pump inlet. It is good practice to clean the system by flushing and filtering, using an external slave pump.

Filling Pump and Removing Air

If the pump is mounted above the fluid level, it should be filled with fluid through the outlet port. If the pump is mounted below the fluid level, the pump outlet fitting (or other downstream fitting or plug) can be loosened to allow fluid to displace the air. It may be necessary to loosen the fill cap on the reservoir to allow the fluid to flow freely. When a solid stream of fluid with no observed air begins to drain through the loosened fitting, the fitting should be retightened. An air bleed valve in the outlet circuit is also recommended to remove trapped air. If such a device is used, the pump should be filled with fluid before start-up. In some cases, it may be possible to prime the pump by running the engine starter for five to ten seconds with the throttle and/or ignition switch in the "off" position. It will be necessary to loosen a fitting or plug in the pump outlet to allow air to escape.

Pump Start-up

All controls should be placed in the neutral position so the pump is unloaded when started. Start the engine and run at low idle. Once the pump is started, it should prime and pump within a few seconds. If it does not, make sure there are no restrictions between the reservoir and the inlet to the pump, and that there are no air leaks in the inlet line and connections. Also, make sure that trapped air can escape from the outlet. Run at low engine idle for approximately five minutes. Then, while observing the reservoir fluid level, operate the implements. Extend all actuators to maximum safe limits to completely fill the system with fluid. Do not run with the fluid level below the "low" limit. Add fluid to the reservoir to bring the fluid to the proper fill level.

Our advantage

01.FACTORY DIRECT PRICE

02.NICE QUALITY

03.QUICK SHIPPING WITHIN 1DAY

04.OEM IS ACCEPTED

05.CUSTOMIZED PRODUCTS

06.NO MOQ,1PC OK.SMALL ORDER WELCOME

07.ONLINE PAYMENT

08.AFTER-SALES SERVICE 24

Series Quick Navigation