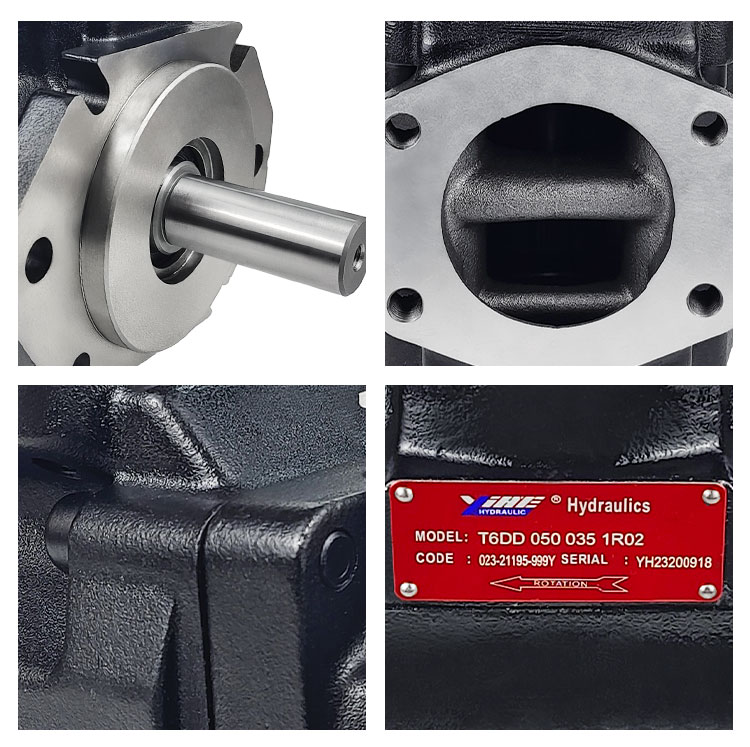

YIHE Hydraulic Double Vane Pump T6DD Series Quantitative Hydraulic Pump T6DD 050 035 1R02

Brand: YIHE

Product origin: China

Delivery time: 5 days

Supply capacity: 300 pcs/day

Model: T6DD

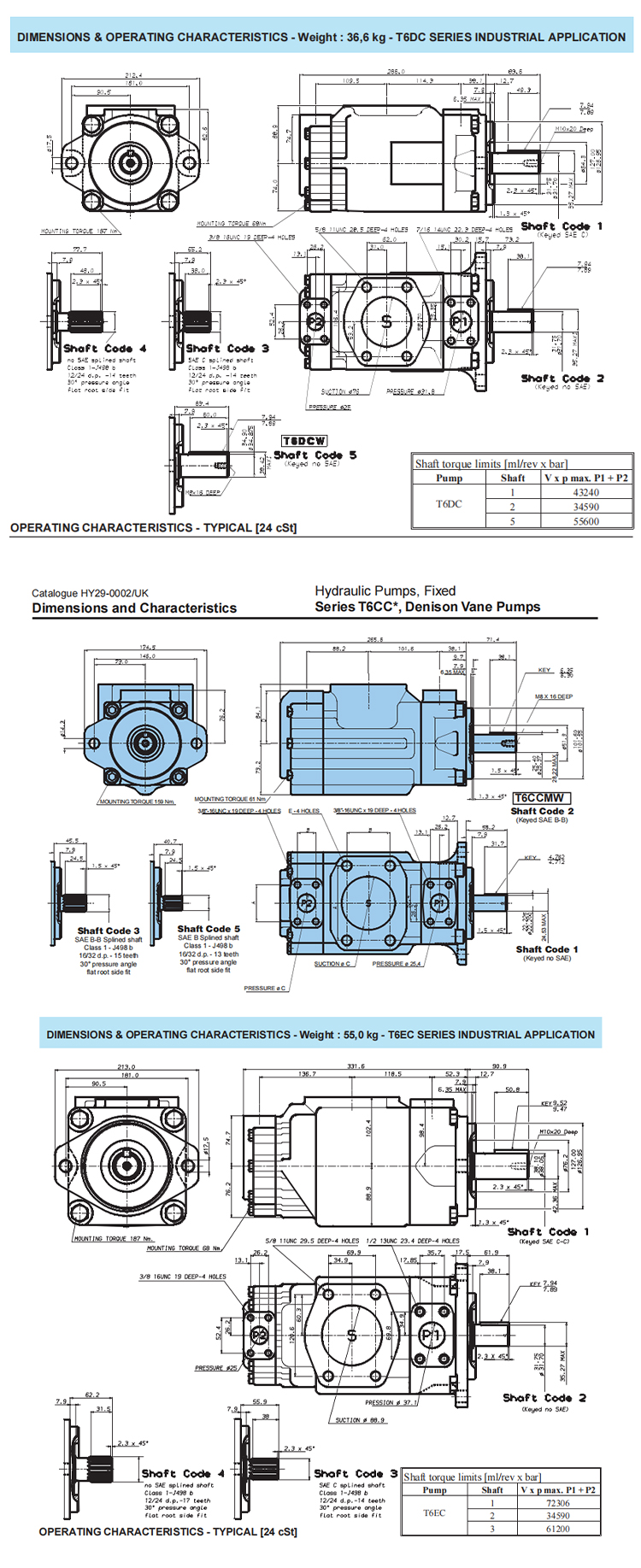

Max Displacement: 10.8 ml/rev - 269ml/rev

Max Working Pressure: 80 Mpa- 24 Mpa

Shaft Speed Range: 600 r/min - 2800 r/min

Rotation: Right and Left From Shaft End

Control Type: DOSING PUMP

Product Type: Vane Pump

Product Details

Featured functions:

High working pressure: Rated working pressure up to 275 bar, which can reduce the hydraulic actuator and hydraulic control

The size of the valve and piping reduces the installation cost. If the working pressure is reduced, the working life can be extended;

High volumetric efficiency: the typical volumetric efficiency is 0.94, which has a high volumetric efficiency even under loading

This increases productivity, reduces heating and reduces operating costs of hydraulic equipment, and allows full pressure conditions

The speed is as low as 600 rpm (vehicle type pump can be as low as 400rpm);

High mechanical efficiency: the typical value is 0.94, reducing the energy loss;

Wide speed range: speed range is 600 ~ 2800 rpm (vehicle type pump is 400 ~ 2800 rpm), combined

The way of installing the pump core assembly with large displacement in the small size housing can optimize the working state and reduce the noise;

Low speed (600 rpm, 400 rpm for vehicle type pump), low pressure and high viscosity (860 cSt, for vehicle type pump)

2000 cSt) Operation capacity - T6 series vane pump can adapt to low temperature conditions, low power consumption and no risk of stalling;

The pressure pulsation is small: about ±2 bar, which can reduce the noise of the hydraulic pipe and extend the other elements in the hydraulic circuit

The service life of the part;

Low noise: improve the safety of the work, increase the degree of acceptance.

Strong anti-pollution ability: This series of pumps adopts double-lip structure of the blade, has a strong anti-pollution ability, service life

Long life;

The optional structural parameters and forms are rich: such as: pump core displacement, transmission shaft form, oil port configuration form, etc.

Easy for users to select according to installation needs;

Diversity of installation forms: there can be 32 installation combinations for double pumps, and as many as for triple pumps

A combination of up to 128 installations reduces costs and increases performance.

A wide range of applications: installation in accordance with SAE J744a and ISO 3019-1 specified 2-hole flange form,

And equipped with a variety of flat key and spline drive shaft for choice. For automotive type pumps, there is also a T-type drive shaft (conforming

SAE J718c) option, allowing direct assembly with tractors (540 to 1000 rpm);

Double shaft seal option: The vehicle type pump has a double shaft seal type (T6*P type), with an oil drain interface, can be straight

Install it on the gear box.

Product Parameters

Instructions for use

To protect your rights please read the following carefully

Pump Start-up Procedure

Preparation Prior to Start-up

The reservoir and circuit should be clean and free of dirt and debris prior to filling with fluid.

Circuit Cleanup

The reservoir should be charged with filtered hydraulic fluid. The fluid level should be sufficient to prevent vortexing at the suction connection to the pump inlet. It is good practice to clean the system by flushing and filtering, using an external slave pump.

Filling Pump and Removing Air

If the pump is mounted above the fluid level, it should be filled with fluid through the outlet port. If the pump is mounted below the fluid level, the pump outlet fitting (or other downstream fitting or plug) can be loosened to allow fluid to displace the air. It may be necessary to loosen the fill cap on the reservoir to allow the fluid to flow freely. When a solid stream of fluid with no observed air begins to drain through the loosened fitting, the fitting should be retightened. An air bleed valve in the outlet circuit is also recommended to remove trapped air. If such a device is used, the pump should be filled with fluid before start-up. In some cases, it may be possible to prime the pump by running the engine starter for five to ten seconds with the throttle and/or ignition switch in the "off" position. It will be necessary to loosen a fitting or plug in the pump outlet to allow air to escape.

Pump Start-up

All controls should be placed in the neutral position so the pump is unloaded when started. Start the engine and run at low idle. Once the pump is started, it should prime and pump within a few seconds. If it does not, make sure there are no restrictions between the reservoir and the inlet to the pump, and that there are no air leaks in the inlet line and connections. Also, make sure that trapped air can escape from the outlet. Run at low engine idle for approximately five minutes. Then, while observing the reservoir fluid level, operate the implements. Extend all actuators to maximum safe limits to completely fill the system with fluid. Do not run with the fluid level below the "low" limit. Add fluid to the reservoir to bring the fluid to the proper fill level.

Company Profile

We are Guangzhou Yisheng Machinery Equipment Co.,Ltd., which located in Foshan City, Guangdong Province, China. We have R&D department with about 5-10 engineers and designers. Our factory have over 100 skilled employees, our production facility have many advanced manufacturing equipments and testing equipments, such as numerical control lathe, the processing center, CNC milling machine, special CNC grinding machine, double grinding machine, automatic 3D measuring instrument, etc..

Our main products are hydraulic variable displacement vane pump, double pump, HVP high pressure variable displacement vane pump, PV2R1 & PV2R2 series,V&VQ series,T6&T7 series, SQP series and VQ series of fixed displacement vane pump and electrical motors for hydraulic application.

Our products are widely used for industrial machinery, NC lathe machine, shoe machinery, wood working machines, plastic machines, construction machines and various hydraulic system machinery. We also able to supply the customized products and services as per your spec. ,we are looking forward to cooperating with your company sincerely.

Why choose us

1.The company established more than 10 years, old brand, worthy of trust,Has more than 1000k+ followers

2.The company's product category is complete, also have a variety of accessories to provide.

3.All products have been passed strict quality test before shipment, make sure high quality.

4.24H customer service,Please feel free to contact me if you have any questions.

5.One-year warranty, we have professional and technical personnel for docking, product quality is hard, and after-sales are guaranteed. After the one-year warranty is over, we can provide maintenance services for customers (this requires a fee).

FAQ

Q: Are you trading company or manufacture?

A: We are factory

Q: How long is your delivery time?

A: Gernally it is 1-2days if the goods are in stock.It is 5-7days if the goods no stock.It is subject to order quantity.

Q: Do you provide sample,Is it free or extra?

A: We are willing to provide samples to test quality first, it is not for free because it is high value products. But sample cost can return in bulk order.

Q: What is the terms of payment?

A: 100% deposit or 30% deposit, 70% before shippment.

Q: How long is the warranty?

A: We offer 12 months warranty.